Biomedical Engineering Reference

In-Depth Information

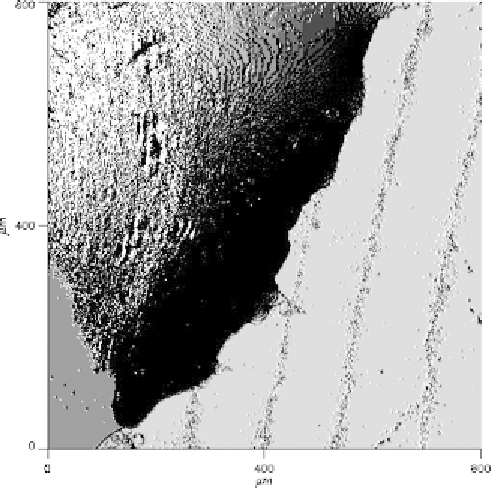

Figure 6.

Microscopic image of a water droplet on a steel surface [4].

this purpose, a thorough topographic characterisation of a surface to be evaluated

with respect to its wetting properties is absolutely essential.

1. Surface Roughness of Solids

Surfaces as physical entities possess many attributes, geometry being one of them.

Surface geometry of real materials by nature is three-dimensional and its detailed

features are termed topography. In engineering field, topography represents the

main external features of a surface which is determined by the description of its

morphology and topometry. In practice, the notion of a surface extends to sub-

layers of solid boundaries and the surface assumes certain internal features [5],

e.g., hardness, residual stress, deformation, chemical composition and reactions,

microstructure, capillary, hydrophobicity, that are often of foremost concern in an

application. Surface topography often interrelates with these features in compli-

cated manners and in three dimensions to define certain engineering properties.

Surface topography is, therefore, significant for surface performance and the impor-

tance of its measurement by means of functional analysis and prediction is obvious.

Engineering surfaces are produced in various ways, typically by machining,

surface treatment and coating. Surface topography modification is therefore per-

formed by material removal, transformation or addition. Combinations of various

machining, treatment and coating operations are employed to produce surfaces with

desired characteristics for a particular application. Surface topography, therefore,

contains 'signatures' of the surface generation process and as such can be used to

Search WWH ::

Custom Search