Biomedical Engineering Reference

In-Depth Information

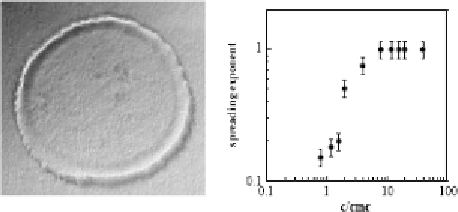

Figure 16.

Left: Photograph of the spreading trisiloxane solution droplet at the highest surfactant

concentration used. Right: power

n

from the evolution of the radius

R

=

C

·

t

n

for the 'superspreading'

of the trisiloxane solutions

versus

concentration [112].

increase in spreading area and decrease in contact angle making it an exceptionally

effective wetting agent. Nevertheless, the debate continues about the nature of the

driving force for superspreading and interpretation of the observed dynamics.

Svitova

et al.

[109] established the essential parameters of trisiloxane wetting:

the critical wetting concentration, CWC, and the critical aggregation concentration,

CAC; the latter being very similar to CMC. CWC is considered to be the con-

centration above which spreading occurs over a (moderately hydrophobic) solid

and liquid substrates. Hence, it is associated with the beginning of superspreading.

CWC, which is reported to be independent of the substrate surface energy, repre-

sents the maximal spreading potential of a trisiloxane surfactant [109, 110]. The

occurrence of the transition from partial wetting to complete spreading at CWC

was first mentioned in [111]. Recently, three regimes of spreading were identified:

(i) complete non-wetting during the spreading process at low concentrations, (ii) a

transition from initial non-wetting to partial wetting at the end of the spreading

process at intermediate concentrations, and (iii) partial wetting both at the begin-

ning and at the end of the spreading process at higher concentrations. Transitions

between different regimes flawlessly correspond to relevant critical concentrations:

CAC or CMC, and CWC [100].

Both the extent and the dynamics of trisiloxane spreading attracted significant

attention over the years. Rafai and Bonn [112, 113] suggested a

R

t

n

power law

to describe trisiloxane spreading with a power

n

larger than 0.1 for concentrations

both above and below CMC (Fig. 16). For very high bulk concentrations, a linear

relation

R

∝

1) was reported.

In [111], three regimes of the spreading dynamics were observed: early stages

where wetting diameter is proportional to

t

n

with

n

in the range 0.12-0.22; dur-

ing the second stage the exponent increases to 0.38-0.58; during the last stage of

spreading the surface roughness and local tension gradients lead to an asymmetric

drop shape and formation of fingers and dendrites. Nikolov

et al.

[77] also reported

finger instabilities during spreading of the drop of aqueous Silwet

®

L-77 solution

on a hydrophobic plate. Stoebe

et al.

[66] observed the small fingers appeared at the

edges of droplets of aqueous trisiloxane solutions, but found the length of fingers

∝

t

(

n

=

Search WWH ::

Custom Search