Biomedical Engineering Reference

In-Depth Information

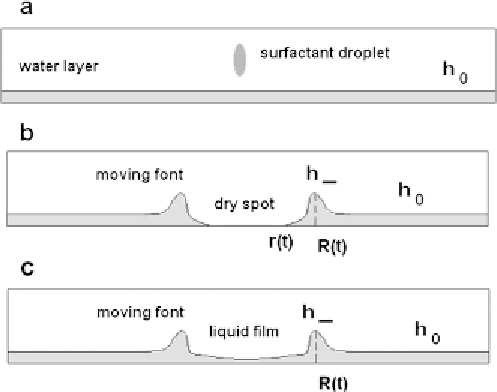

Figure 8.

(a) A small droplet of aqueous surfactant solution is deposited on a top of thin aqueous

layer of thickness

h

0

; (b) dry spot formation in the centre: cross section of the system:

R(t)

—radius

of a circular moving front,

r(t)

—radius of dry spot in the centre,

H

—the height of the moving front;

(c) the same as in the previous case (b) without dry spot formation in the centre.

reach

0.75. It was also shown in [46], that formation of the dry spot in the centre

is determined by the speed of the first stage: the higher this speed, the higher the

probability to have dry spot formation. Hence, the dry spot forms in the case of

soluble surfactants and does not form in the case of insoluble surfactants.

The observations in [46] differed from the earlier theoretical model [48], thus the

influence of surfactant solubility and disintegration of micelles was incorporated to

improve on the previous theoretical model. According to theoretical predictions

[46], low soluble surfactant produce faster first and second stages. Low soluble sur-

factant (Tween

®

20) produced a power law exponent 0

.

73

∼

0

.

01, being close to the

maximum attainable spreading rate 0.75 predicted theoretically. For the highly sol-

uble surfactant DTAB, the solubility was most significant during the second stage

where the spreading front reached some final position and did not move any further

in the agreement with theoretical predictions.

Chan and Borhan [49] deduced that insoluble monolayers enhance the over-

all spreading rate. They developed a mathematical model for surfactant enhanced

spreading that suggests two additional mechanisms which influence the spreading

rate: the development of positive surface curvature near the moving contact line,

which produces a favourable radial pressure gradient within the drop, and the sur-

factant convection in a vicinity of the moving contact line. Accumulation of the

surfactant at the contact line, due to surface convection, leads to faster spreading

of a drop. Seguin

et al.

[50] performed experiments using ionic and non-ionic sur-

factants in different solvents. For ionic surfactants, effect of a charged head group

on micellisation was obvious, while for non-ionic pure ethylene glycol appeared to

±

Search WWH ::

Custom Search