Biomedical Engineering Reference

In-Depth Information

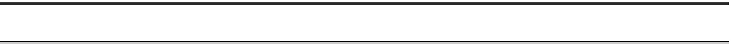

Ta b l e 2 .

Reactivity of pure metals in contact with SiC [167-169]

Category

Reactivity type

Metal

1

No reaction

Au, Ag, Sn, Pb, Ge

2

Me

+

SiC

→

silicide

+

C

Ni, Fe, Cu, Co

3

Me

+

SiC

→

Si

+

carbide

V, Al, Nb

4

Me

+

SiC

→

silicide

+

carbide

Zr, Ti, Hf, Cr, Ta, W, Mo

2. Silicon Carbide

Silicon carbide is of great technological significance due to its good overall chem-

ical, thermal and mechanical properties, which make it a suitable candidate for

aggressive environments. It is used both as a structural and as a functional material;

indeed, it is currently used in high-temperature applications, such as metal-matrix

composites, heat exchangers, aerospace and electronic applications, etc. [159-161].

A case in point is nuclear applications, with demands in thermal shock resistance,

radiation stability and low neutron-induced activation [162-166]. Therefore, join-

ing (brazing) SiC to SiC or to SiC

f

, to refractory metals or to superalloys, can lead

to optimized highly performing applications.

The reactivity of the pure metals with SiC directly affects the interfacial reac-

tions, wetting and bonding. Based on the research results of Kurokawa and Na-

gasaki [167] and the reviews of Rabin [168] and Li and Zhang [169], the pure

metals may be classified into four categories according to their reactivity with SiC,

as shown in Table 2. The metals of the first category show almost no chemical re-

actions with SiC under the experimental conditions. In the second category, only

stable silicides can form at the interface; the silicon and carbon originated from the

SiC matrix tend to diffuse into the metal component; the carbon can exist as a solid

solution provided the solubility of carbon in the metal is high enough, otherwise it

will segregate as graphite in the liquid phase or even at the solid-liquid interface

after saturation. In the third one, the carbides are the main products, as most silicon

dissolves into the metal and forms carbides, although sometimes a small quantity

of silicide can form [170]. In the fourth category, a mixed layer containing silicides

and carbides often forms at the interface by reaction and mutual diffusion between

the metal and the ceramic.

A recent review on SiC wetting by liquid metals and alloys [171] has shown that

the wettability of SiC depends on three main factors:

(1) the condition of the SiC surface,

(2) the presence of adsorption phenomena at the solid-liquid interface,

(3) the presence of reaction/dissolution phenomena between the liquid phase and

the solid substrate.

Search WWH ::

Custom Search