Biomedical Engineering Reference

In-Depth Information

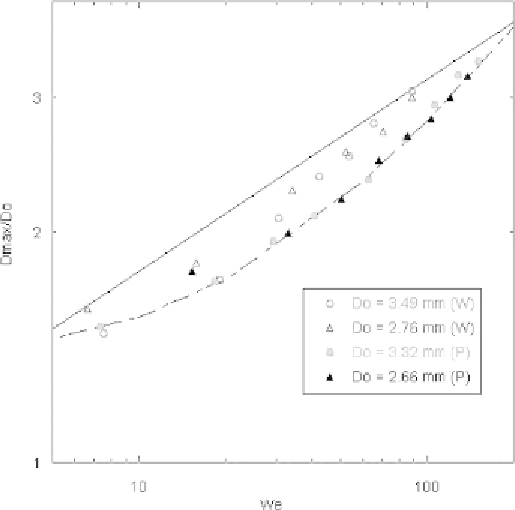

Figure 17.

Maximum spreading diameter of Leidenfrost drops of different diameter: comparison be-

tween water (W) and a 200 ppm PEO solution (P).

water drops, in particular for We

>

30, the maximum spreading diameter of vis-

coelastic drops follows the trend predicted by the energy conservation approach.

In any case it must be observed that for We

>

20 the maximum spreading diame-

ter of viscoelastic drops is systematically smaller than that of water drops having the

same impact Weber number. This means that the fraction of impact kinetic energy

(which is proportional to the Weber number) converted into surface energy (which

is proportional to the area of the drop surface at maximum spreading) is smaller.

In principle, such reduction of the surface energy at maximum spreading could

be interpreted as the consequence of increased dissipation during the expansion

stage due to the higher elongational viscosity of the polymer solution, providing

an independent confirmation of the theory originally proposed to explain the anti-

rebound effect of polymer additives [29, 30, 33, 37, 38]. However, this does not

exclude that the missing surface energy may be stored elsewhere, for example as

elastic energy.

In order to get a deeper insight of the energy re-distribution upon impact, one

can observe what happens during the rebound stage, when surface energy is con-

verted back to kinetic energy and propels the drop off the surface. In particular,

the maximum height of the centre of mass of the drop allows one to calculate ex-

actly the fraction of surface energy recovered as mechanical energy during this

stage,

E

rec

=

mgH

max

. Figure 18 shows the maximum height of the drop centre of

Search WWH ::

Custom Search