Biomedical Engineering Reference

In-Depth Information

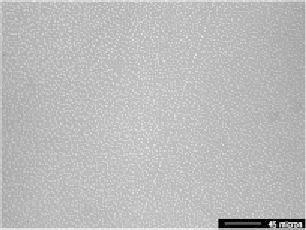

(A)

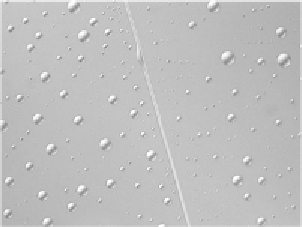

(B)

(C)

Figure 13.

(A) Oil/silanized silicon wafer. (B) Oil/mica. (C) Oil/metal sputtered wafer.

tems as like the microscopic origin of macroscopic wetting phenomena may be

collected in the huge production of the same Authors already cited in these pages

[211-214] among many others that focused their attention, for example, over the

friction problems of spreading phenomena of layered wetting structures. It may be

anyway useful to underline some points that affect almost each microscopic wetting

experience:

•

the sample surface status,

•

the deposition methodology,

•

the contact angle value determination.

As an example Fig. 13(A, B, C) shows how do look, at metallographic micro-

scope analysis and the same magnifying factor, paraffin oil drops deposited by the

author with vaporizing and condensing technique over three different solid sur-

faces, respectively: silanized silicon wafer (Fig. 13A), muscovite mica (Fig. 13B)

and metal sputtered silicon wafer (Fig. 13C). By the simple visual evaluation of

these three very unlike solid surfaces it can be immediately perceived how the same

fluid, almost inert over all of the analyzed substrates, provides completely differ-

ent behaviors as a function of the solid surface energy features. Silanes (Fig. 13A),

when correctly deposited over a solid surface either by dip-coating either by vapor-

Search WWH ::

Custom Search