Biomedical Engineering Reference

In-Depth Information

Figure 2.

Dimensionless drop diameter,

β

, plotted against time for shear-thinning drops (

K

=

5

.

064 Pas

n

,

n

=

0

.

084) impacting on glass and parafilm-M surfaces [16].

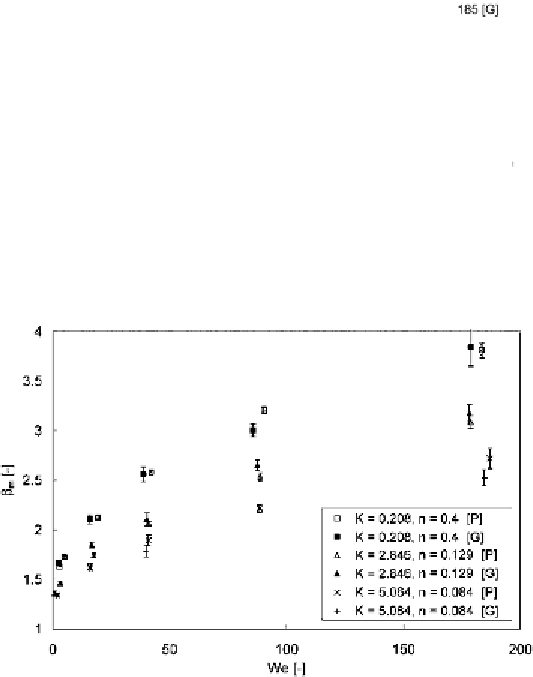

Figure 3.

Maximum spreading diameter of shear-thinning drops impacting on substrates of different

wettability (glass and parafilm) [16].

is barely noticeable for impacts on the glass surface, where the slow capillary driven

spreading continues directly after the fast spreading of the inertial expansion phase.

In particular, the maximum spreading diameter, reported with respect to the We-

ber number in Fig. 3, can be considered the same for the two surfaces, within

experimental error.

Increasing the mass fraction of Xanthan gum increases the consistency coeffi-

cient

K

, however it also decreases the power law index

n

. In other words, fluids

become thicker but at the same more shear-thinning. Again, fluids exhibiting large

degrees of shear-thinning (i.e., with a value of the power-law exponent close to

Search WWH ::

Custom Search