Biomedical Engineering Reference

In-Depth Information

(A)

(B)

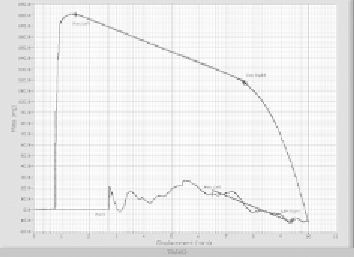

Figure 12.

(A) DCA on ultrasonic cleaned sample. (B) DCA on a ultrasonic

+

plasma cleaned.

of water over high energetic quartz surfaces, differently treated in order to reach

various hydroxylation grades. It came out that a water condensed film of vari-

ous thicknesses, dependent upon the surface hydroxylation grades, formed over

these substrates and macroscopic contact angles greatly changed as a function of

it. Specifically the contact angle was found decreasing as like the condensed ice-

like structured film was increasing its thickness.

As a simple example of how these effects matter also at macroscale size Fig. 12

shows how dynamic wetting tests performed with Wilhelmy Apparatus may change

as a function of the surface energy status. Figure 12A shows the result for the sam-

ple as it behaved after a simple cleaning procedure by ultrasonic bath in pure water

(Advancing contact angle close to 88 deg) while Fig. 12B shows the behavior to

the same test of the same sample after a 30 sec, 60 W oxygen plasma cleaning

procedure at 13.56 MHz (advancing contact angle close to 46 deg). The advancing

profile looks much more disturbed in Fig. 12B, a signal that stronger and more spe-

cific liquid-solid interactions exists. The expected consequence is a reduced contact

angle value, as effectively appears. Advancing contact angle reduction confirms the

greater interaction between the fluid and the solid surface, so the liquid spreads bet-

ter. The plasma treatment effectively removed some adsorbed pollutants revealing

the inner surface energy features without causing the damages that some aggres-

sive cleaning fluids like the wide known 'Piranha Solution' (H

2

SO

4

+

H

2

O

2

)may

cause more on sample surfaces.

On the other hand the same oxygen plasma treatment when inadequately per-

formed [190] may determine misleading results. As an example, when applied over

ceramic and glasses it may greatly increase the number of superficial -OH groups

(yet removable by high temperature heating), determining a more hydrophilic be-

havior than expected while over pure metallic surfaces the same treatment may

reduce the wetting features due to a lower surface energy uniformly oxidized sur-

face transformation [191, 192].

In these conditions sample preparation problems are always possible but it is

highly preferable to deal with a defined, known, even if eventually modified surface

Search WWH ::

Custom Search