Biomedical Engineering Reference

In-Depth Information

(A)

(B)

(C)

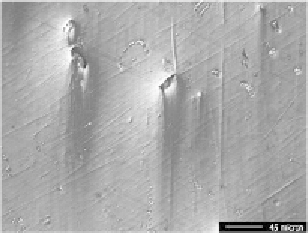

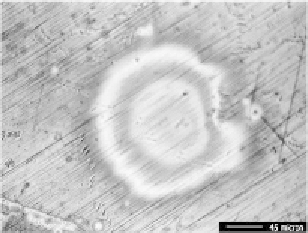

Figure 2.

Microscopic

vs.

nanoscopic comparison of a natural and mechanically polished metal sur-

face.

reformulation of this Theory followed by a best fit approach able to determine the

acid-base parameters of both liquid and solid without any further information on

materials involved in the experimental activity.

F. Experimental Application

Apart of mica [(KAl

2

Si

3

AlO

10

(OH)

2

] and silicon wafers for electronic application

most of the materials cannot be considered as 'flat and homogeneous' as they may

eventually look in a macroscopic analysis. When macroscopic (centimetric) wide

droplets lie on a surface different from a clearly rough one the problem of the real

surface morphology seems far away. When, on the other hand, we deal with mi-

cro/nanoscopic drops or, even easier, we focus our attention to the

triple line

, i.e.,

the visible perimeter contour between solid surface-liquid-environmental fluid, the

morphology topic turns up.

Figure 2 illustrates the problem as it may show up for a bulk metal surface

(molybdenum in this case). At a first macroscopic insight the substrate sample

was originally looking flat but on a microscopic analysis (Fig. 2A) several bumps

and defects were found emerging by the surface. After a normal smoothing treat-

ment (Fig. 2B) the surface appeared to be bump free but evident regular scratches

Search WWH ::

Custom Search