Biomedical Engineering Reference

In-Depth Information

(a)

(b)

1 mm

10 µm

(c)

20

10

0

-10

-20

0

1

2

Length [mm]

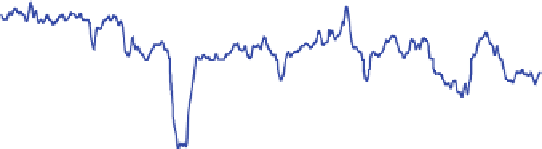

Fig. 2 Surface structure of the carrier Sponceram HA

determined by a focus variation with an

InfiniteFocus microscope, b by scanning electron microscopy and c by profile measurements

From a macroscopic point of view, the surface of the Sponceram HA

received

exhibits a wavy structure with large local defects (Fig.

2

). Profile measurements

determined defects with a diameter of up to 150 lm and a depth of up to 100 lm.

The scanning electron microscopy (SEM) picture shows a disordered structure of

coarse grains exhibiting a diameter of about 1-2 lm and a length of 5-10 lm.

Density determination revealed a porous structure with relative density of 43%.

Relatively small macropores allow no ingrowth of cells; for bone tissue, for

example, pore diameters of more than 300 lm are recommended [

9

]. As cartilage

is an avascular tissue, a scaffold which supports angiogenesis by an interconnected

porosity with adequate pore diameters is not required for nutrient supply [

40

].

Using the cultivation principle described above, cartilage-carrier constructs

were generated on top of Sponceram HA

carrier and compared to cartilage

cultivated without a carrier. Significant differences could be observed in the

mass and the thickness of tissue-engineered cartilage. The wet weight of cartilage

grown without a carrier compared to cartilage grown on top of a carrier was

33.4 ± 1.7 mg and 18.6 ± 4.3 mg, respectively. The thickness was determined to

be 2.4 ± 0.1 mm for unsupported cartilage and 0.7 ± 0.2 mm for cartilage-carrier

constructs. With a factor of 3.5 for the Young's modulus and 2.3 for the glycos-

aminoglycan (GAG) content, values were significantly lower for the cartilage

grown on top of the carrier compared to cultivation without a carrier (Fig.

3

).

Search WWH ::

Custom Search