Biomedical Engineering Reference

In-Depth Information

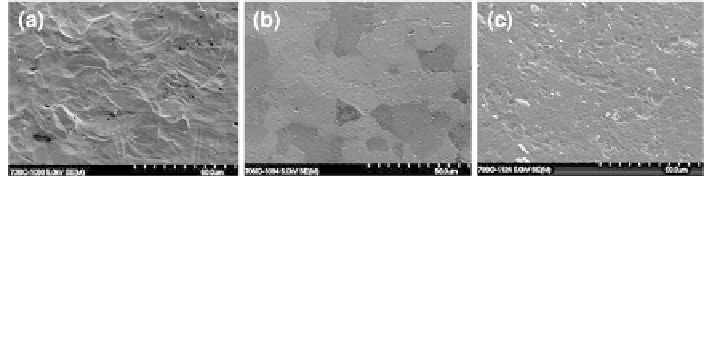

Fig. 2 Scanning electron micrographs of titanium and its polished counterparts. a Standard

commercially pure titanium as used in clinics (R

a

& 1 lm). b Electropolished titanium—

implants are submerged in an electrolyte solution and a charge is applied. Material is removed

from the surface at a rate that is dependent on the electrical conductivity of the metal. c Paste

polished titanium—a mechanically abrasive method that physically removes material from the

surface which is based on the relative hardness of the metal. Polishing results in an R

a

of

approximately 0.2-0.3 lm

method that involves submerging the implants in an electrolyte solution to which a

charge is applied. Material is removed from the surface at a rate that is dependent

on the electrical conductivity of the metal or its alloying elements. In contrast,

paste polishing is a mechanically abrasive method that physically removes surface

features. The removal of material is based on the relative hardness of the metal and

it alloying elements. Essentially, a 'hard' material will provide resistance to the

physical abrasion, which helps produce a homogenous smoothened surface

(Fig.

2

). Both these techniques were employed to reduce the surface micror-

oughness of titanium and two of its alloys, TAN and titanium-15% molybdenum.

It was found that compared with microrough control surfaces, polishing of tita-

nium and its alloys significantly increased the occurrence of soft tissue capsule

formation in hand fracture fixation devices in an in vivo rabbit model in the

tibia [

79

]. Furthermore, polishing significantly reduces the force required for

removal of conventional and locked screws as well as intramedullary nails from

sheep tibial bone after short-term (6, 12 and 18 weeks) and long-term (6, 12 and

18 months) implantation [

78

,

80

,

81

]. Histologically, it was observed that polished

implants supported fibro-osseointegration or the occurrence of a very thin fibrous

layer (sometimes only one to three cells thick) between the bone and implant

without loss of implant stability. These results also challenge, therefore, the

general notion that direct bone bonding is required for stable fixation (Figs.

3

,

4

).

3.3 Roughness Spectrum

Cell-material interaction studies have clearly defined that a microrough surface is

inductive for osteoblast differentiation, and that this phenomenon is echoed by

microrough implants in vivo. However, a clear definition describing what con-

stitutes a 'rough' or 'smooth' surface (millimetres, micrometres, nanometres) is

distinctly lacking. One of the main reasons for this omission is that different

Search WWH ::

Custom Search