Biomedical Engineering Reference

In-Depth Information

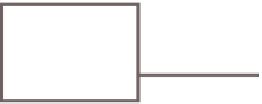

Stress head and optical encoder

(position sensitive strain detector)

Circulating water

inlet and outlet for

Peltier temperature

control system

Upper fixture (plate)

Lower fixture (plate)

Peltier temperature

control system

Computer

A typical controlled-stress instrument.

Figure 2.15

More generally the stress wave will have a frequency-dependent phase difference

δ

(0 <

δ

<90°)sothat

δ

, or more usually tan

δ

, is a measure of the viscous/elastic ratio for

the material at the given frequency

. The elastic (in-phase) and viscous (out-of-phase)

components of the stress wave are separable, and they de

ω

ne the shear storage modulus G

0

as the ratio of in-phase stress to strain and the shear loss modulus G

00

as out-of-phase stress

to strain. Clearly the values of both G

0

and G

00

will in turn depend upon

ω

, the oscillatory

shear (radial) frequency

-

with

ω

equal to 2

π

times the frequency f (in Hz).

ned G

0

and G

00

, we can evaluate a number of other commonly used

rheological parameters, since all are interrelated. For example, G

*

, the amplitude of the

complex modulus, is given by

Having de

q

G

ðÞ

2

2

G

j¼

j

þ

G

0

ðÞ

;

ð

2

:

27

Þ

and

G

00

G

0

¼

tan

ðδÞ:

ð

2

:

28

Þ

In the early days of oscillatory rheometry, the phase angle

, rather than its tangent, was

an experimentally observed parameter. Finally, the amplitude of the complex viscosity

δ

η

*

is given by

G

j

ω

:

j

j¼

j

ð

2

:

29

Þ

This helps to de

ne and subsequently measure the so-called mechanical spectrum

-

the trace of (log) G

0

and (log) G

00

versus (log)

ω -

andtoestablishwhetherornota

Search WWH ::

Custom Search