Biomedical Engineering Reference

In-Depth Information

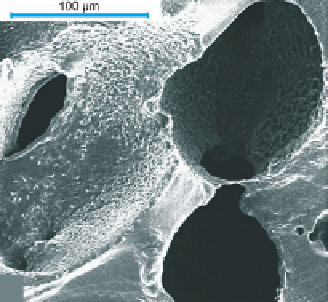

Figure 11.13

Scanning electron micrograph of a superporous hydrogel (SPH). Reproduced with permission from

Omidian et al.(

2005

) © 2005 Elsevier.

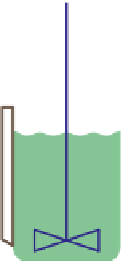

4. Foaming aid, foam stabilizer

3. Cross-linker

5. Oxidant

2. Neutralization

1. Monomer dilution

6. Reductant

7. Bicarbonate

SPH

Figure 11.14

Steps in the production of a superporous hydrogel (SPH). Reproduced with permission from

Omidian et al.(

2005

) © 2005 Elsevier.

added to generate gas bubbles. Dispersion and dissolution of HCO

3

−

increases the pH of

the reaction medium to a level at which the initiator decomposes faster. When the

formation of initiator radicals reaches a certain level, polymerization proceeds rapidly

and the reacting mixture becomes viscous over time. At the same time, HCO

3

−

reacts

with the acid component to produce the CO

2

required for the blowing process.

The two processes, i.e. the cross-linking reaction (gelation) and foaming processes, need

to be controlled so that 80% of the foaming develops before gelation. Then the rest of the

foaming occurs, the cross-linking reaction takes place and temperature increases by 5

10°C.

As cross-linking proceeds further and the temperature reaches its maximum, the foam turns

into a

-

flexible, rubber-like material. Then the synthesized foam is added to a non-solvent,

usually ethanol, in several batches until it is completely dehydrated, to stabilize the product

and prevent it from shrinking. This results in a solid, brittle, porous product which can be

ground into particles (like SAP particles), sliced into absorbent sheets or machined to a

desired shape and size. Dried SPHs swell fast in water and to a size a few hundred times their

Search WWH ::

Custom Search