Biomedical Engineering Reference

In-Depth Information

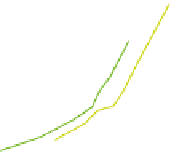

200

P/G

=

0

P/G

=

0.1

P/G

=

0.3

P/G

=

0.5

P/G

=

0.7

P/G

=

1

150

100

50

0

30

40

50

60

c

gel

(wt%)

70

80

90

100

Onset of melting temperature determined by differential scanning calorimetry (DSC) of gelatin

Figure 7.18

films containing various amounts of glycerol. The ratio P/G is the mass of plasticizer (glycerol) to

the mass of gelatin. Reprinted from Coppola et al.(

2008

) with permission of John Wiley & Sons.

agreement with the previous description of the gels. However, when the gelatin concen-

tration exceeds 50 wt%, T

m

increases sharply, e.g. reaching 180°C at c

gelatin

= 98 wt% (only

the bound water is left) for non-plasticized

films (P/G= 0). These very high melting

temperatures are related to the formation of bundles of triple helices, which aggregate

when the

films start to dry and the overall volume decreases (Pezron et al.,

1991

).

The melting temperatures for

films containing glycerol increase with the ratio P/G for a

given gelatin composition, as do the glass transition temperatures. Interpretation of the

phase diagram of plasticized

films highlights the role of hydrogen bonds between water

or glycerol and the protein residues. The

films are characterized by three states of

aggregation according to their concentration, temperature and plasticizer content: bun-

dles of triple helices, randomly oriented triple helices and random coils, which can be in

either a glassy or a rubbery state (Coppola et al.,

2008

).

7.3

Agarose

Agarose is a linear polysaccharide which can be extracted by treating agarophyte red algae

with alkali. It consists mainly of repeated sequences of the two residues

β

(1

3)-linked

→

d-galactose and

L-galactose residues (

Figure 7.19

). Agarose

is the purest material from the usual extracted commercial product agar-agar (or simply

'

α

(1

4)-linked 3,6-anhydro-

α

→

-

cant amount of the sulphated form, sometimes referred to as agarose sulphate, and some-

times agaropectin. Almost all the world

agar

'

). This product, like the carrageenan series described in

Chapter 5

, contains a signifi-

is production of agar is concentrated around Japan,

and the article by Matsuhashi (

1990

) is an interesting survey of both history and applications.

Agarose itself has therefore to be separated from a mixture of crude agar-agar which

also includes agarose sulphate, but this can be achieved following alkali treatment of the

original algae extract, eventually leaving pure agarose. This is assumed to be chemically

and electrically neutral, although it still contains some

'

'

rogue residues

'

of the sulphated

Search WWH ::

Custom Search