Biomedical Engineering Reference

In-Depth Information

amount of time before implantation, allowing more time for the scaffold

to degrade and cartilage to be formed (Figure 1.1).

1.3

Designing Scaffold for Cartilage Tissue

Engineering

Scaffold should be designed to provide a 3D environment which is suitable

for cartilaginous tissue production. In an ideal case the scaffold should have

a number of essential characteristics which are as follows: (i) promote cells

attachment, proliferation, viability and differentiation, and ECM production,

(ii) allow diffusion of nutrients and waste products, (iii) adhere and integrate

with the surrounding native cartilage, (iv) provide suffi cient mechanical integ-

rity depending on the defect location, and, fi nally, (v) controlled degradation.

Several researchers [9, 10] have found that the scaffolds degradation plays

an important role in cartilage regeneration. Scaffold degradation can occur

hydrolytically or enzymatically, and by controlling degradation tempo-

rally and spatially, scaffolds can accelerate and direct new tissue growth

[9, 10]. Degradable scaffold has improved ECM distribution compared to

completely non-degradable ones [9], and scaffolds with a slower degrada-

tion rate yielded cartilage of greater thickness in an osteochondral defect

model as reported by Solchaga and coworkers [10].

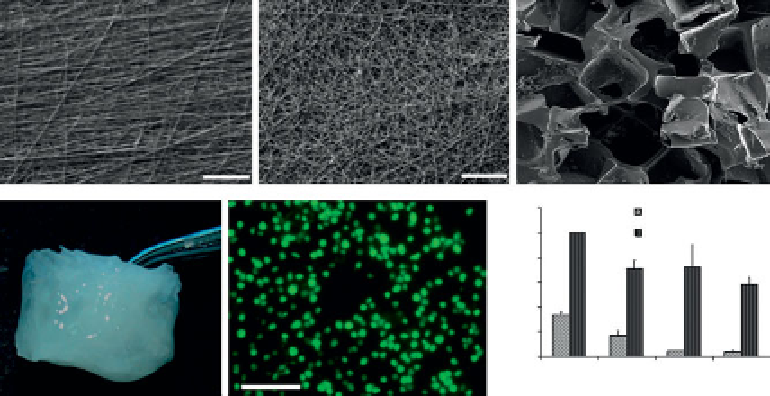

Three different forms of polymeric scaffold, namely, hydrogels, sponges

and fi brous meshes (Figure 1.2), have been fabricated and investigated

(

a

)

(

b

)

(

c

)

1.2

No TGF-

3

With TGF-

β

(

d

)

(

e

)

(

f

)

1.0

β

3

0.8

0.6

0.4

0.2

0.0

7

14

21

28

100

μ

m

Time (day)

Figure 1.2

Representative examples of different forms of scaffolds utilized for

cartilage tissue engineering. SEM images of (a, b) aligned and unaligned fi brous

scaffolds, (c) sponge, (d) hydrogel scaffold, (e) skeletal cells growth (rounded cell

morphology) within hydrogel, and (f)

col2a1

gene expression. Reprinted with

permission from [6, 7, 12]

.

Search WWH ::

Custom Search