Biomedical Engineering Reference

In-Depth Information

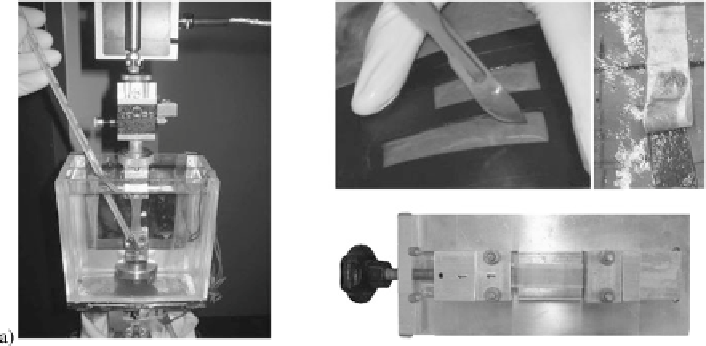

Fig. 26.4

Experimental setup and sample preparation for uniaxial tensile testing. (

a

) Situation on

the uniaxial testing machine: the installed sample inside the bio-chamber, the clamping interfaces,

the

xy

-positioning stage, and the load cell are visible. (

b

) Excision of the capsule samples from

the parenchyma using a scalpel and a plastic template. On the

right

, a sample with paper backing

is shown on the site of extraction. The underlying parenchyma is visible. (

c

) The custom-made

assembling jig for precise and gentle alignment and mounting of the samples on the clamps

26.2.2.1 Uniaxial Tests

The liver capsule samples were tested in a Zwick 1456 universal materials test-

ing machine. The axial force was measured with a 50 N load cell. A custom-made

biochamber was used to simulate physiological conditions. During testing, the sam-

ples remained entirely immersed in the saline with its temperature controlled to

37.0 °C. A two-axis linear positioning stage was installed on the load cell to pre-

cisely align the sample with the tensile axis of the machine in order to prevent shear-

ing. The test setup is shown in Fig.

26.4

. Samples were delicately excised using a

surgical scalpel and a thin plastic sheet template. The samples were approximately

15 mm in width and 60 mm in length. The sample thickness was assumed equal

within the same sample and was assessed by averaging three measurements taken at

random locations using a micrometer caliper. The time between sample preparation

and mechanical test never exceeded 1 h.

A preload of 0.065 N was applied at the beginning of the tests; note that

the choice of the preload has significant influence on the definition of the refer-

ence configuration and thus on the strain calculation. Tests were carried out un-

der displacement-controlled conditions with an elongation rate of 0

.

5 %/s nominal

strain. In order to obtain a preconditioned state of the tissue samples, the samples

underwent 10 cycles of loading and unloading between 0 and 15 % nominal strain

prior to ultimate loading until tissue rupture. Given the sample width of

w

15 mm,

the displacement of the cross bar, the free gauge length at preload, and the exerted

tensile force, the nominal strain and the nominal membrane tension in uniaxial ten-

sion were computed.

=