Biomedical Engineering Reference

In-Depth Information

surface layers. However, they can significantly contrib-

ute (either positively or negatively) to the bioresponse

to the surface.

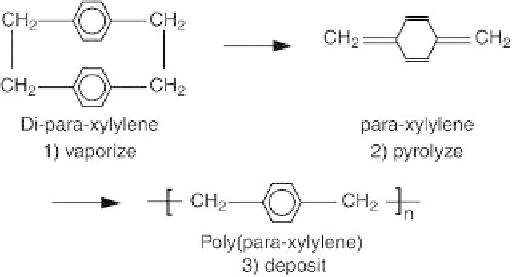

deposition, and polymerization of the monomer, di-

para

-

xylylene (DPX), according to the following reaction:

Conversion coatings

Conversion coatings modify the surface of a metal into

a dense oxide-rich layer that imparts corrosion pro-

tection, enhanced adhesivity, altered appearance (e.g.,

color) and sometimes lubricity to the metal. For exam-

ple, steel is frequently phosphated (treated with phos-

phoric acid) or chromated (with chromic acid).

Aluminum is electrochemically anodized in chromic,

oxalic, or sulfuric acid electrolytes. Electrochemical an-

odization may also be useful for surface-modifying tita-

nium

The DPX monomer is vaporized at 175

C and 1 torr,

pyrolyzed at 700

C and 0.5 torr, and finally deposited on

a substrate at 25

C and 0.1 torr. The coating has excellent

electrical insulation and moisture barrier properties and

has been used for protection of implant electrodes (Loeb

et al.,

1977b; Nichols

et al.,

1984) and implanted elec-

tronic circuitry (Spivack and Ferrante, 1969). Recently,

a parylene coating has been used on stainless steel car-

diovascular stents between the metal and a drug-eluting

polymer layer.

and

Ti-Al

alloys

(Bardos,

1990;

Kasemo

and

Lausmaa, 1985).

The conversion of metallic surfaces to ''oxide-like,''

electrochemically passive states is a common practice

for base-metal alloy systems used as biomaterials.

Standard and recommended techniques have been

published (e.g., ASTM F4-86) and are relevant for most

musculoskeletal load-bearing surgical implant devices.

The background literature supporting these types of

surface passivation technologies has been summarized

(von Recum, 1986).

Base-metal alloy systems, in general, are subject to

electrochemical corrosion (M / M

þ

þ

e

) within saline

environments. The rate of this corrosion process is re-

duced 10

3

-10

6

times by the presence of a dense, uni-

form, minimally conductive, relatively inert oxide

surface. For many metallic devices, exposure to a mineral

acid (e.g., nitric acid in water) for times up to 30 minutes

will provide a passivated surface. Plasma-enhanced sur-

face passivation of metals, laser surface treatments, and

mechanical treatments (shot peening) can also impart

many of these characteristics to metallic systems.

The reason that many of these surface modifications

are called ''oxide-like'' is that the structure is complex,

including OH, H, and subgroups that may, or may not, be

crystalline. Since most passive surfaces are thin films

(5-500 nm) and are transparent or metallic in color, the

surface appears similar before and after passivation.

Further details on surfaces of this type can be found in

Sections 3.1.4 and 3.2.9.

Laser methods

Lasers can rapidly and specifically induce surface changes

in organic and inorganic materials (Picraux and Pope,

1984; Dekumbis, 1987; Chrisey

et al,

2003). The ad-

vantages of using lasers for such modification are the

precise control of the frequency of the light, the wide

range of frequencies available, the high energy density,

the ability to focus and raster the light, the possibilities

for using both heat and specific excitation to effect

change, and the ability to pulse the source and control

reaction time. Lasers commonly used for surface modi-

fication include ruby, neodymium: yttrium aluminum

garnet (Nd: YAG), argon, and CO

2

. Treatments are

pulsed (100 nsec to picoseconds pulse times) and con-

tinuous wave (CW), with interaction times often less

than 1 msec. Laser-induced surface alterations include

annealing, etching, deposition, and polymerization.

Polymers, metals, ceramics, and even tooth dentin have

been effectively surface modified using laser energy. The

major considerations in designing a laser surface treat-

ment include the absorption (coupling) between the laser

energy and the material, the penetration depth of the

laser energy into the material, the interfacial reflection

and scattering, and heating induced by the laser.

Parylene coating

Parylene (

para-

xylylene) coatings occupy a unique

niche in the surface modification literature because of

their wide application and the good quality of the

thin film coatings formed (Loeb

et al.

, 1977a; Nichols

et al.

, 1984). The deposition method is also unique

and involves the simultaneous evaporation, pyrolysis,

Patterning

Essentially all of the surface modification methods de-

scribed in this section can be applied to biomaterial