Biomedical Engineering Reference

In-Depth Information

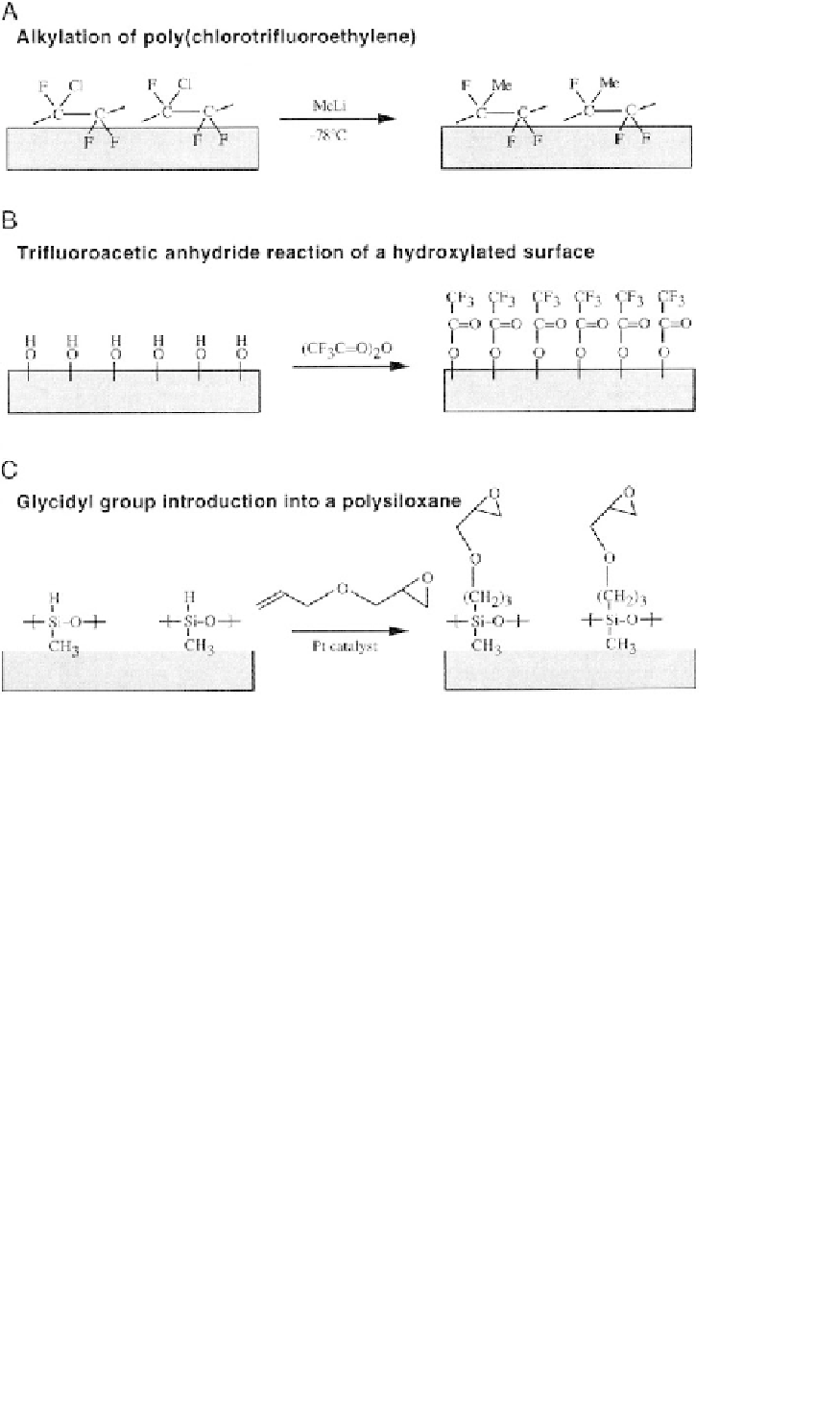

Fig. 3.2.14-3 Some specific chemical reactions to modify surfaces.

(see Section 3.2.9). An example of thermal spray coating

on titanium is seen in Gruner (2001).

of adsorbed surface water), a structure similar to that

shown in

Fig. 3.2.14-4

can be formed. However, if more

water is present, a thicker silane layer can be formed

consisting of both Si-O groups bonded to the surface and

silane units participating in a ''bulk'', three-dimensional,

polymerized network. The initial stages in the formation

of a thicker silane film are suggested by the further re-

action of the group at the right side of

Fig. 3.2.14-4

D with

solution-phase silane molecules. Without careful control

of silane liquid purity, water concentration, and reaction

conditions,

Silanization

Silane treatments of surfaces involve a liquid-phase

chemical reaction and are straightforward to perform and

low cost. A typical silane surface modification reaction is

illustrated in

Fig. 3.2.14-4

. Silane reactions are most often

used to modify hydroxylated surfaces. Since glass, silicon,

germanium, alumina, and quartz surfaces, as well as many

metal oxide surfaces, are rich in hydroxyl groups, silanes are

particularly useful for modifying these materials. Numer-

ous silane compounds are commercially available, permit-

ting a broad range of chemical functionalities to be

incorporated on surfaces (

Table 3.2.14-4

). The advantages

of silane reactions are their simplicity and stability, attrib-

uted to their covalent, cross-linked structure. However,

the linkage between a silane and an hydroxyl group is also

readily subject to basic hydrolysis, and film breakdown

under some conditions must be considered (Wasserman

et al.,

1989).

Silanes can form two types of surface film structures. If

only surface reaction occurs (perhaps catalyzed by traces

thicker

silane

films

can

be

rough

and

inhomogeneous.

A new class of silane-modified surfaces based upon

monolayer silane films and yielding self-assembled, highly

ordered structures is of particular interest in precision

engineering of surfaces (Pomerantz

et al.,

1985; Maoz

et al.,

1988; Heid

et al.,

1996). These self-assembled

monolayers (SAMs) are described in more detail later in

this section.

Many general reviews and basic science studies on sur-

face silanization are available (Arkles, 1977; Plueddemann,

1980; Rye

et al.

, 1997). Applications for silanized surface-

modified biomaterials are on the increase and include cell

attachment

(Matsuzawa

et al.

,

1997;

Hickman

and