Biomedical Engineering Reference

In-Depth Information

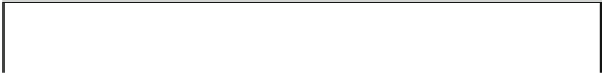

Material, fiber

PLA

Minimum

Maximum

Average

PLA, carbon

PLA, inorganic

PLA, PLA

PGA, PGA

POE

Cortical bone

316L Stainless

Nylon 6

UHMW PE

0

2

0

4

0

6

0

8

0

100

120

140

160

180

200

Flexural modulus (GPa)

Fig. 3.2.12-7 Representative flexural moduli of absorbable polymer composites (from Daniels, A. U., Melissa, K. O., and

Andriano, K. P. (1990). Mechanical properties of biodegradable polymers and composites proposed for internal fixation of bone.

J. Appl. Biomater. 1(1): 57-78.).

Their review revealed that unreinforced biodegrad-

able polymers are initially 36% as strong in tension as

annealed stainless steel, and 54% in bending, but only 3%

as stiff in either test mode. With fiber reinforcement,

highest initial strengths exceeded those of stainless steel.

Stiffness reached 62% of stainless steel with non-

degradable carbon fibers, 15% with degradable inorganic

fibers, but only 5% with degradable polymeric fibers.

Most previous work on absorbable composite fracture

fixation has been performed with PLLA polymer. PLLA

possesses three major characteristics that make it a po-

tentially attractive biomaterial:

those of pure polymer plates.

In vivo,

the matrix degraded

and the plates lost rigidity, gradually transferring load to

the healing bone. However, the mechanical properties of

such chopped fiber plates were relatively low; conse-

quently, the plates were only adequate for low-load situ-

ations.

Zimmerman

et al.

(1987)

used composite theory

to determine an optimum fiber layup for a long fiber

composite bone plate. Composite analysis suggested the

mechanical superiority of a 0

/

45

laminae layup. Al-

though the 0

/

45

carbon/PLA composite possessed

adequate initial mechanical properties, water absorption

and subsequent delamination degraded the properties

rapidly in an aqueous environment (

Fig. 3.2.12-8

). The

fibers did not chemically bond to the matrix.

In an attempt to develop a totally absorbable com-

posite material, a calcium-phosphate-based glass fiber has

been used to reinforce PLA. Experiments were pursued

to determine the biocompatibility and in vitro degrada-

tion properties of the composite (Zimmerman

et al.,

1991). These studies showed that the glass fiber-PLA

composite was biocompatible, but its degradation rate

was too high for use as an orthopedic implant.

Shikinami and Okuno (2001)

, have produced mini-

plates, rods, and screws made of HA poly(

L

-lactide).

These composites have been principally applied for in-

dications such as repair of bone fracture in osteosynthesis

and fixation of bony fragments in bone grafting and

osteotomy, exhibiting total resorbability and osteological

1.

It degrades in the body at a rate that can be

controlled.

2.

Its degradation products are nontoxic, biocompatible,

easily excreted entities. PLA undergoes hydrolytic

deesterification to lactic acid, which enters the lactic

acid cycle of metabolites. Ultimately it is metabo-

lized to carbon dioxide and water and is excreted.

3.

Its rate of degradation can be controlled by mixing it

with PGA polymer.

PLLA polymer reinforced with randomly oriented

chopped carbon fiber was used to produce partially de-

gradable bone plates (

Corcoran

et al.

, 1981

). It was

demonstrated that the plates, by virtue of the fiber re-

inforcement, exhibited mechanical properties superior to