Biomedical Engineering Reference

In-Depth Information

devices, such as bone plates and screws, at much lower

cost than comparable metallic devices.

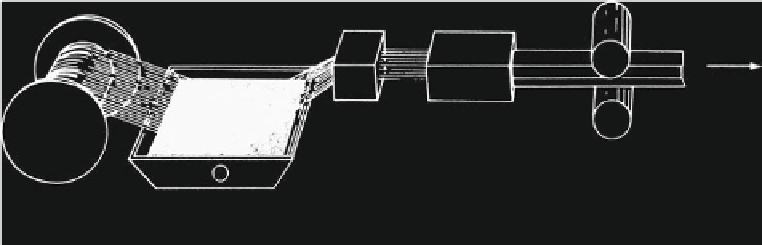

Continuous pultrusion is a process used for the man-

ufacture of fiber-reinforced plastics of constant cross

section such as structural shapes, beams, channels, pipe,

and tubing. In this process, continuous-strand fibers are

impregnated in a resin bath and then are drawn through

a heated die, which determines the shape of the finished

stock (

Fig. 3.2.12-3

). Highly oriented parts cut from this

stock can then be used in other structures or they can be

used alone in such applications as intramedullary rodding

or pin fixation of bone fragments.

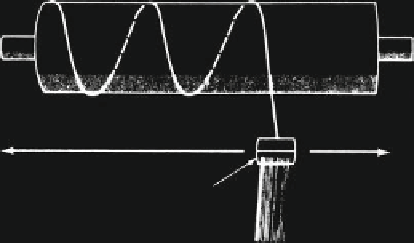

Mandrel

Traversing

carriage

Resin-impregnated

fibers

Fig. 3.2.12-2 Filament-winding process for producing fiber-

reinforced composite materials.

Mechanical and physical properties

of composites

In this process, the fiber reinforcement is fed through

a resin bath and then wound on a suitable mandrel

(

Fig. 3.2.12-2

). When sufficient layers have been applied,

the wound mandrel is cured. The molded part is then

stripped from the mandrel. The high degree of fiber

orientation and high fiber loading with this method

produce extremely high tensile strengths. Biomedical

applications for this process include intramedullary rods

for fracture fixation, prosthetic hip stems, ligament

prostheses, intervertebral disks, and arterial grafts.

Continuous fiber composites

Laminated continuous fiber-reinforced composites are

described from either a micro- or macromechanical point

of view. Micromechanics is the study of composite ma-

terial behavior wherein the interaction of the constituent

materials is examined on a local basis. Macromechanics is

the study of composite material behavior wherein the

material is presumed homogeneous and the effects of the

constituent materials are detected only as averaged ap-

parent properties of the composite. Both the micro-

mechanics

Closed-mold processes

There are many closed-mold methods used for producing

fiber-reinforced plastic materials. The methods of most

importance to biomedical composites are compression

and injection molding and continuous pultrusion. In

compression molding, the previously described prepregs

are arranged in a two-piece mold that is then heated

under pressure to produce the laminated part. This

method is particularly useful for use with thermoplastic

matrices. In injection molding the fiber-matrix mix is

injected into a mold at elevated temperature and pres-

sure. The finished part is removed after cooling. This is

an extremely fast and inexpensive technique that has

application to chopped fiber-reinforced thermoplastic

composites. It offers the possiblity to produce composite

and

macromechanics

of

experimental

laminated composites will be discussed.

Micromechanics

There are two basic approaches to the micromechanics

of composite materials: the mechanics of materials and

the elasticity approach. The mechanics-of-materials ap-

proach embodies the concept of simplifying assump-

tions regarding the hypothesized behavior of the

mechanical system. It is the simpler of the two and

the traditional choice for micromechanical evaluation.

Orientation

Heated

die

Pull rollers

Resin dip

tank

Reinforcement

supply

Fig. 3.2.12-3 The pultrusion process for producing fiber-reinforced polymer composite materials. Fibers impregnated with polymer are

fed into a heated die and then are slowly drawn out as a cured composite material with a constant cross-sectional shape.