Biomedical Engineering Reference

In-Depth Information

The route and conditions under which synthetic HA is

produced will greatly influence its physical and chemical

characteristics. Factors that affect the rate of resorption

of the implant include physical factors such as the

physical features of the material (e.g., surface area,

crystallite size), chemical factors such as atomic and ionic

substitutions in the lattice, and biological factors such as

the types of cells surrounding the implant and location,

age, species, sex, and hormone levels.

The thermodynamic stability of the various calcium

phosphates is summarized in the form of the phase dia-

gram shown in

Fig. 3.2.10-8

. The binary equilibrium

phase diagram between CaO and P

2

O

5

gives an indication

of the compounds formed between the two oxides, and

by comparing this with

Table 3.2.10-7

it is possible to

identify the naturally occurring calcium phosphate min-

erals. The diagram does not indicate the phase boundaries

of apatite due to the absence of hydroxyl groups.

However, from the binary diagram an indication may

be obtained of the stability of other calcium phosphates

with temperature.

The stoichiometry of HA is highly significant where

thermal processing of the material is required. Slight

imbalances in the stoichiometric ratio of calcium and

phosphorus in HA (from the standard molar ratio of

1.67), can lead to the appearance of either a or

b-TCP on heat treatment. Many early papers concerning

the production and processing of HA powders reported

problems in avoiding the formation of these extraneous

phases (Jarcho

et al.

, 1976; De With

et al.

, 1981a, b;

Peelen

et al.

, 1978). However, using stoichiometric HA

it should be possible to sinter, without phase purity

problems, at temperatures in excess of 1300

C.

20000

15000

1000

5000

0

10

20

30

2 Theta (degrees)

40

50

60

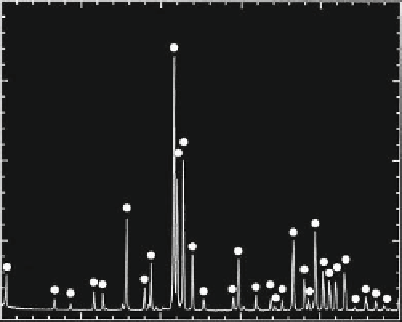

Fig. 3.2.10-9 X-ray diffraction of HA.

X-ray diffraction (

Fig. 3.2.10-9

) and infra-red spec-

troscopy (

Fig. 3.2.10-10

) should be used to reveal the

phase purity and level of hydroxylation of HA. Kijima

and Tsutsumi (1979) used these techniques to study HA

sintered at different temperatures and reported that

after sintering at 900

C, the material was fully hydrox-

ylated, but after sintering at temperatures higher than

this, dehydroxylation occurred. Dehydration of HA,

produced by processes such as high temperature solid

state reaction, result in the formation of oxyhydrox-

yapatite: Ca

10

(PO

4

)

6

(OH)

2

2x

O

x

V

x

(where V is a hy-

droxyl vacancy). HA has a

P6

3

/m

space group: This

signifies that the lattice is primitive Bravais, there is

a sixfold axis parallel to the

c

axis and

a

1/2 (3/6)

translation along the length of the

c

axis (a screw axis)

with a mirror plane situated perpendicular to the screw

axis and the

c

axis. The

a

and

c

parameters for HA are

0.9418 nm and 0.6884 nm, respectively.

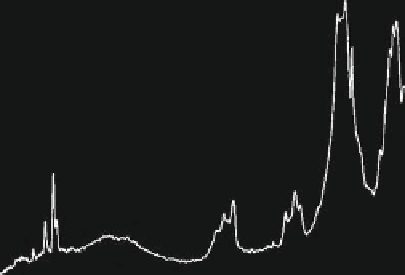

−

PO

3

ν

3

ν

4

EP-1

ν

1

−

PO

3

ν

2

−

(

ν

3

)

CO

2

OH

−

(Stretch)

A & B

−

(Absorbed)

CO

2

OH

−

(Libration)

A

B

A & B

H

2

O

(Absorbed)

−

(

ν

2

)

CO

2

Fig. 3.2.10-8 Phase equilibrium diagram of calcium phosphates

in a water atmosphere. Shaded area is processing range to

yield HA-containing implants. (After K. de Groot. 1988. Ann. N. Y.

Acad. Sci. 523: 227.)

4000 3600

3200

2800 2400 2000

Wavenumber cm

−

1

1600

1200

800

400

Fig. 3.2.10-10 Typical FT-IR spectrum for HA.