Biomedical Engineering Reference

In-Depth Information

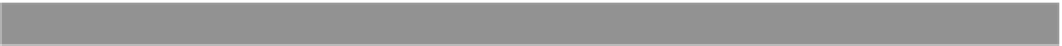

Table 3.2.9-2 Typical mechanical properties of implant metals

a

Material

ASTM

designation

Condition

Young's

modulus

(GPa)

Yield

strength

(MPa)

Tensile

strength

(MPa)

Fatigue

endurance limit

(at 10

7

cycles, R

[ L

1

c

)

(MPa)

Stainless steel

F745

Annealed

190

221

483

221-280

F55, F56, F138, F139

Annealed

190

331

586

241-276

30% Cold worked

190

792

930

310-448

Cold forged

190

1213

1351

820

Co-Cr alloys

F75

As-cast/annealed

210

448-517

655-889

207-310

P/M HIP

b

253

841

1277

725-950

F799

Hot forged

210

896-1200

1399-1586

600-896

F90

Annealed

210

448-648

951-1220

Not available

44% Cold worked

210

1606

1896

586

F562

Hot forged

232

965-1000

1206

500

Cold worked, aged

232

1500

1795

689-793 (axial tension

R ¼ 0.05, 30 Hz)

Ti alloys

F67

30% Cold-worked Grade 4

110

485

760

300

F136

Forged annealed

116

896

965

620

Forged, heat treated

116

1034

1103

620-689

a

Data collected from references noted at the end of this section, especially table 1 in

Davidson and Georgette (1986)

.

b

P/M HIP; Powder metallurgy product, hot-isostatically pressed.

c

R is defined as

s

min

/

s

max

.

desired shape (e.g., femoral stems for artificial hips, oral

implants, dental partial bridgework). The sometimes

intricately shaped molds are made by fabricating a wax

pattern to near-final dimensions of the implant and then

coating (or investing) the pattern with a special ceramic,

which then holds its shape after the wax is burned out

prior to castingdhence the ''lost wax'' name of the pro-

cess. Molten metal is poured into the ceramic mold

through sprues, or pathways. Then, once the metal has

solidified into the shape of the mold, the ceramic mold is

cracked away and processing of the metal continues

toward the final device.

Depending on the exact casting details, this process can

produce at least three microstructural features that can

strongly influence implant properties, often negatively.

First, as-cast F75 alloy (

Figs. 3.2.9-6

and

3.2.9-7A

)

typically consists of a Co-rich matrix (alpha phase) plus

interdendritic and grain-boundary carbides (primarily

M

23

C

6

, where M represents Co, Cr, or Mo).

There can also be interdendritic Co and Mo-rich sigma

intermetallic, and Co-based gamma phases. Overall, the

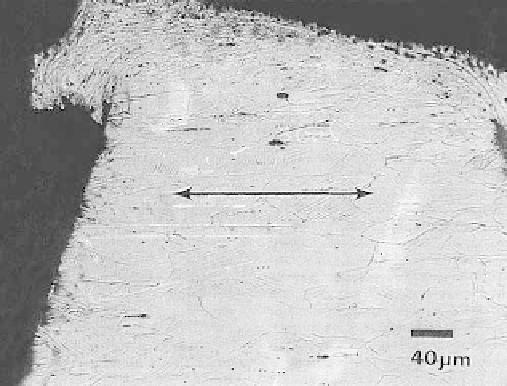

Fig. 3.2.9-5 Evidence of textured grain structure in 316L stainless

steel ASTM F138, as seen in a longitudinal section through a

cold-worked bone screw. The long axis of the screw is indicated

by the arrow.