Biomedical Engineering Reference

In-Depth Information

Yarn

flat or texturized

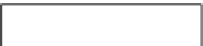

Table 3.2.4-6 Sample test methods for large-diameter textile grafts

Test

Required

regulatory

testing

Routine

quality

testing

Fabric

woven or knit

Visual inspection for defects

X

X

Initial cleaning

Water permeability

X

X

Longitudinal tensile strength

X

Compaction, if rqd.

Burst strength

X

X

Crimping

Usable length

X

X

Relaxed internal diameter

X

X

Pressurized internal diameter

X

Heat setting

Wall thickness

X

Suture retention strength

X

External support

Kink diameter/radius

X

Final cleaning

Dynamic compliance

X

Animal trials

X

Inspection

packaging and sterilization

Shelf life

X

Sterility

X

X

Fig. 3.2.4-12 Typical graft finishing operation.

Biomaterials/toxicity and

pyrogen testing

X

X

polymer, textile, and final product will be safe and ef-

ficacious.

Table 3.2.4-6

is a list of the suggested test

methods used in the development of a textile-based

vascular

(disposable) products, and wovens for reusable items.

Most of these barrier-type fabrics are made from cellu-

lose (cotton, viscose rayon, and wood pulp), P, and

PP fibers. Many fabrics contain finishes that render them

water repellent depending on the clinical need. Addi-

tionally, such fabrics must generally be fire retardant

because of the risk of explosions due to exposure to

flammable gases used for anesthesia. In applications such

as facemasks, the fabric must minimize the passage of

bacteria through the mask. This can be ensured by en-

gineering the appropriate pore size distribution in the

filtration fabric (

Schreuder-Gibson, 2002

). Antibacterial

coatings are also placed on surgical drapes to minimize

the risk of wound contamination. Drapes and protective

apparel typically require some assembly that can be done

either through conventional sewing or by ultrasonic

seaming methods. The latter method is preferred for

those products used in sterile fields since the holes cre-

ated by conventional sewing needles can render the fabric

permeable to liquids and liquid-borne pathogens. Drapes

are usually constructed of a nonwoven fabric laminated

to a plastic film to ensure that they are impervious to

blood and other fluids. Another common use of textiles is

in the fabrication of adhesive tapes. These tapes generally

graft

for

large

vessel

replacement

(

ANSI/

AAMI/ISO, 2001

).

Applications

The application of fibers and biotextiles as components

for implant devices is widespread and covers all aspects

of medicine and health care. Textiles are used as basic

care items such as drapes, protective apparel, wound

dressings, and diapers and in complex devices such as

heart valve sewing rings, vascular grafts, hernia repair

meshes, and percutaneous access devices.

Drapes and protective apparel

The most common nonimplantable medical use of tex-

tiles is for protective surgical gowns, operating room

drapes, masks, and shoe covers. Nonwovens and wovens

are most frequently used for these applications, with

nonwovens being the material of choice for single-use