Biomedical Engineering Reference

In-Depth Information

4.0

3.5

3.0

2.5

2.0

1.5

1.0

0.5

Polyester core (PBT)

Polypropylene core (Type 1)

Polypropylene core (Type 2)

Expanded PTFE

0.0

-0.5

0

1

2

3

4

5

6

7

8

9

Weeks

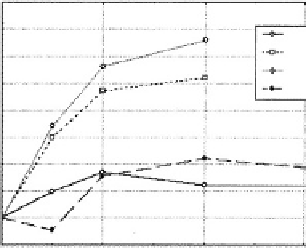

Fig. 3.2.4-5 Creep characteristics of various graft materials

(Weinberg,1998).

A

Figure 3.2.4-5

demonstrates the creep characteristics of

grafts fabricated from expanded polytetrafluoroethylene

(e-PTFE), polyester, and a BCF containing PP yarns. In

the case of the first BCF design (see later section), the PP

was used as the nonabsorbable core material and the main

structural component of the fiber.

Figure 3.2.4-5

repre-

sents the outer diameter of a series of pressurized graft

materials as a function of time. Classical graft materials

such as PET and e-PTFE show no creep over time,

whereas the PP-based materials continue to creep over

time, making them unacceptable for long-term vascular

implants. However, in other applications such as for

hernia repair meshes and sutures, PP has been used very

successfully. It should be noted that in the second-gen-

eration BCF design, the core material was changed to

poly(butylene terephthalate) (

King

et al.

, 2000

).

B

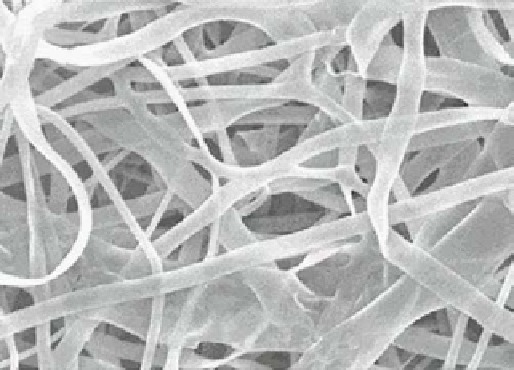

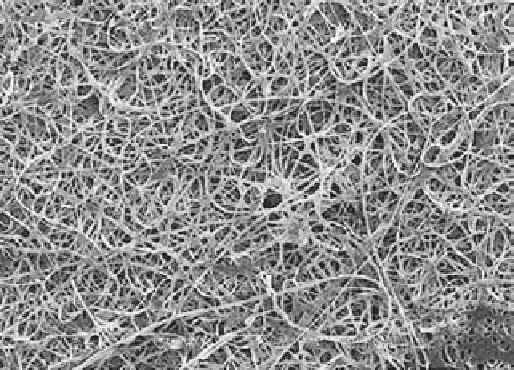

Fig. 3.2.4-4 Electrospun fibers from biomimetic-elastin peptide.

Absorbable synthetic fibers

Another series of synthetic fibers used in clinical appli-

cations are constructed from polymers that are designed

to be absorbed over time when placed in the body. They

classically have been used as sutures, but have also been

used experimentally for neurological, vascular graft, and

tissue scaffold applications.

Table 3.2.4-3

is a list of

bioabsorbable polymers that have been used in the past

to fabricate medical devices. When in contact with the

body, these polymers degrade either by hydrolysis or by

enzymatic degradation into nontoxic by products. They

break down or degrade either through an erosion process

that starts on the exterior surface of the fiber and con-

tinues until the fiber has been totally absorbed, or by a bulk

erosion mechanism in which the process is autocatalytic

and starts in the center of the fiber. Caution should be

exercised when using these types of materials. In vascular

applications, the risk of distal embolization to the micro-

vasculature may occur if small pieces of the polymer break

off during the erosion or absorption process.

Escherichia coli.

The protein has been electrospun into

fibers with diameters varying between 3 nm and 200 nm

(

Huang

et al.

, 2000

)(

Fig. 3.2.4-4

).

Polymer and fiber selection

When deciding on a polymer and fiber structure to be

incorporated into the construction of a medical fabric,

careful consideration of the end use is necessary. Issues

such as the duration of body contact, device mechanical

properties, fabrication restrictions, and sterilization

methods must be considered. To illustrate this point,

PP has been successfully used in many implantable ap-

plications such as a support mesh for hernia repair. Ex-

perience has shown that PP has excellent characteristics

in terms of tissue compatibility and can be fabricated into

a graft material with adequate mechanical strength. A

critical question remaining is whether the graft will

remain

stable

and

survive

as

a

long-term

implant.