Biomedical Engineering Reference

In-Depth Information

O

O

O

O

-C-N CH

2

N-C-O-CH

2

-CH

2

-CH

2

-CH

2

-O- -C-N CH

2

N-C-O- -CH

2

-CH

2

-CH

2

-O —

x

y

H

H

H

H

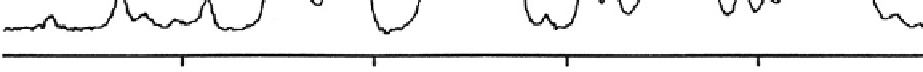

H1 H2 H5 H6 C1 C2

S1 S2 S3

H3 H4

Hard Segment

Chain Extender

Soft Segment

Carbon Label

Shift (ppm)

65

27

71

41

136

129

119

154

165

25

PTMO - CH

2

adjacent to urethane (S1)

PTMO - internal CH

2

(S2)

PTMO - external CH

2

(S3)

MDI CH

2

(H1)

MDI quarternary ring (H2/H5)

MDI protonated ring (H3)

MDI protonated ring (H4)

MDI urethane carbonyl (H6)

BD external CH

2

(C1)

BD external CH

2

(C2)

200

150

100

50

0

Frequency in ppm relative to TMS

Fig. 3.2.2-14

13

C NMR spectrum and peak assignation of a polyurethane [diphenylmethane diisocyanate (MDI, hard segment),

polytetramethylene oxide (PTMO, soft segment), butanediol (BD, chain extender)]. Obtained by cross-polarization magic angle

spinning of the solid polymer. (From Okamoto, D. T., Ph.D. thesis, University of Wisconsin, 1991. Reproduced with permission.)

polymers. Samples are subjected to cyclic deformation at

a fixed frequency in the range of 1-1000 Hz. The stress

response is measured while the cyclic strain is applied

and the temperature is slowly increased (typically at

2-3 degrees/min). If the strain is a sinusoidal function

of time given by:

A typical plot of tan d versus temperature will

display maxima at

T

g

and at lower temperatures where

small-scale motions (secondary relaxations) can occur.

Additional peaks above

T

g

, corresponding to motions in

the crystalline phase and melting, are seen in semi-

crystalline materials. DMA is a sensitive tool for charac-

terizing polymers of similar chemical composition or

for detecting the presence of moderate quantities of

additives.

DSC is another method for probing thermal transi-

tions of polymers. A sample cell and a reference cell are

supplied energy at varying rates so that the temperatures

of the two cells remain equal. The temperature is in-

creased, typically at a rate of 10-20 degrees/min over the

range of interest, and the energy input required to

maintain equality of temperature in the two cells is

recorded. Plots of energy supplied versus average tem-

perature allow determination of

T

g

, crystallization tem-

perature (

T

c

), and

T

m

.

T

g

is taken as the temperature at

which one half the change in heat capacity,

DC

p

, has

occurred. The

T

c

and

T

m

are easily identified, as shown in

3

ð

u

Þ¼

3

o

sin

ð

u

tÞ

(3.2.2.7)

where 3 is the time-dependent strain, 3

o

is the strain

amplitude, u is the frequency of oscillation, and

t

is time,

the resulting stress can be expressed by:

s

ð

u

Þ¼

s

o

sin

ð

u

t þ

d

Þ

(3.2.2.8)

where s is the time-dependent stress, s

o

is the amplitude

of stress response, and d is the phase angle between stress

and strain. For Hookean solids, the stress and strain are

completely in phase (d

¼

0), while for purely viscous

liquids, the stress response lags by 90

. Real materials

demonstrate viscoelastic behavior where d has a value

between 0

and 90

.