Biomedical Engineering Reference

In-Depth Information

A

B

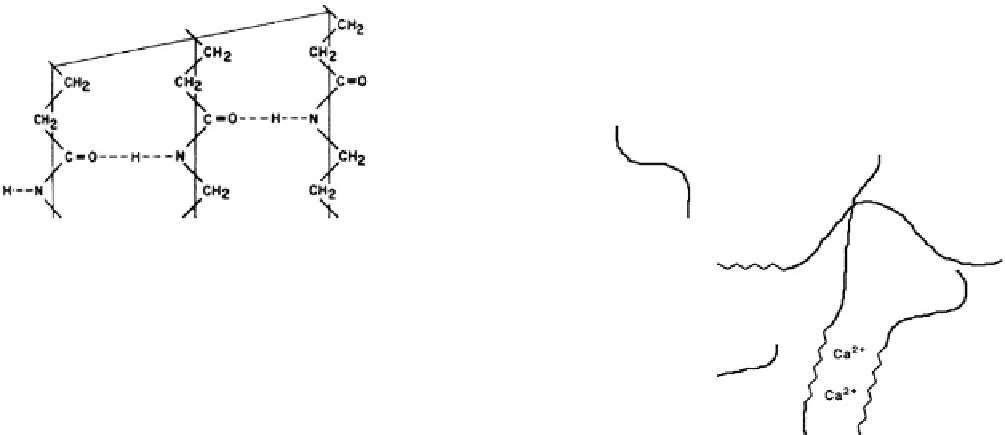

Fig. 3.2.2-7 (A) Hydrogen bonding in nylon-6,6 molecules in a triclinic unit cell:

s

form. (From L. Mandelkern, An Introduction to

Macromolecules, Springer-Verlag, 1983, p. 43, with permission.) (B) Ionic aggregation giving rise to physical cross-links in copolymers.

Mechanical properties

structure resulting from chemical cross-links and chain

entanglements prevents large-scale movement or flow.

Thus, rubbery polymers tend to exhibit a lower modulus,

or stiffness, and extensibilities of several hundred per-

cent, as shown in

Table 3.2.2-1

. Rubbery materials may

also exhibit an increase of stress prior to breakage as

a result of strain-induced crystallization assisted by mo-

lecular orientation in the direction of stress. Glassy and

semicrystalline polymers have higher moduli and lower

extensibilities.

The ultimate mechanical properties of polymers at

large deformations are important in selecting particular

The tensile properties of polymers can be characterized

by their deformation behavior (stress-strain response

(

Fig. 3.2.2-9

). Amorphous, rubbery polymers are soft

and reversibly extensible. The freedom of motion of the

polymer chain is retained at a local level while a network

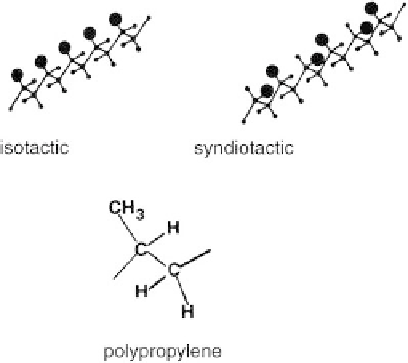

Fig. 3.2.2-8 Schematic of stereoisomers of PP. (From

F. Rodriguez, Principles of Polymer Systems, Hemisphere Publ.,

1982, p. 22, with permission.)

Fig. 3.2.2-9 Tensile properties of polymers.