Biomedical Engineering Reference

In-Depth Information

initiation, propagation, and termination to give the final

polymer product. The initiators can be free radicals,

cations, anions, or stereospecific catalysts. The initiator

opens the double bond of the monomer, presenting an-

other ''initiation'' site on the opposite side of the mono-

mer bond for continuing growth. Rapid chain growth

ensues during the propagation step until the reaction is

terminated by reaction with another radical, a solvent

molecule, another polymer molecule, an initiator, or an

added chain transfer agent. PVC, PE, and PMMA are

relevant examples of addition polymers used as bio-

materials. The polymerization of MMA to form PMMA

is shown in

Fig. 3.2.2-2

A.

Condensation polymerization is completely analogous

to condensation reactions of low-molecular-weight mole-

cules. Two monomers react to form a covalent bond, usually

with elimination of a small molecule such as water, hydro-

chloric acid, methanol, or carbon dioxide. Nylon and PET

(

Fig. 3.2.2-2

B) are typical condensation polymers and are

used in fiber or fabric form as biomaterials. The reaction

continues until almost all of one reactant is used up. There

are also polymerizations that resemble the stepwise growth

of condensation polymers, although no small molecule

is eliminated. Polyurethane synthesis bears these charac-

teristics, which is sometimes referred to as polyaddition

or rearrangement polymerization (

Brydson, 1995

).

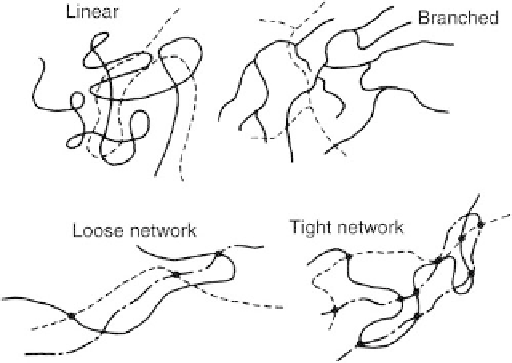

The choice of polymerization method strongly affects

the polymer obtained. In free radical polymerization,

a type of addition polymerization, the molecular weights

of the polymer chains are difficult to control with pre-

cision. Added chain transfer agents are used to control

the average molecular weights, but molecular weight

distributions are usually broad. In addition, chain transfer

reactions with other polymer molecules can produce

undesirable branched products (

Fig. 3.2.2-3

) that affect

the ultimate properties of the polymeric material. In

contrast, molecular architecture can be controlled very

Fig. 3.2.2-3 Polymer arrangements. (From F. Rodriguez,

Principles of Polymer Systems, Hemisphere Publ., 1982, p. 21,

with permission.)

precisely in anionic polymerization. Regular linear chains

with PI indices close to unity can be obtained. More

recent methods of living free radical polymerizations

called ATRP and RAFT may also yield low PIs.

Polymers produced by addition polymerization can be

homopolymers, i.e., polymers containing only one type of

repeat unit, or copolymers with two or more types of

repeat units. Depending on the reaction conditions and

the reactivity of each monomer type, the copolymers can

be random, alternating, graft, or block copolymers, as

illustrated in

Fig. 3.2.2-4.

Random copolymers exhibit

properties that approximate the weighted average of

those of the two types of monomer units, whereas block

copolymers tend to phase separate into a monomer-A-

rich phase and a monomer-B-rich phase, displaying

properties unique to each of the homopolymers.

Figure 3.2.2-5

shows the repeat units of many of the

homopolymers used in medicine.

AAAAAAAAAAAAAA

B

homopolymer

B

AABABAABBAAABBBA

AAAAAAAAAAAA

random copolymer

graft copolymer

ABABABABABABABAB

AAAABBBBBBAAAAA

alternating copolymer

block copolymer

Fig. 3.2.2-4 Possible structures of polymer chains.