Biomedical Engineering Reference

In-Depth Information

fracture toughness parameter is a function of the appar-

ent crack propagation stress and the crack depth and

shape. It is called the critical stress intensity factor (K

lc

)

and has units of Pa

A

m

3/2

(

Meyers and Chawla,

1984

). For materials that exhibit extensive plastic de-

formation at the crack tip, an energy-based parameter,

the J integral, can be used. The energy absorbed in

impact fracture is also a measure of toughness, but at

higher loading rates (

Newey and Weaver, 1990

).

morN

$

O

Time

B

Ultimate tensile

strength range

Effect of fabrication on strength

A general concept to keep in mind when considering the

strength of materials is that the process by which a ma-

terial is produced has a major effect on its structure and

hence its properties (

Newey and Weaver, 1990

). For

example, plastic deformation of most metals at room

temperature flattens the grains and produces strength-

ening while reducing ductility. Subsequent high-

temperature treatment (annealing) can reverse this

effect. Polymers drawn into fibers are much stronger in

the drawing direction than are undrawn samples of the

same material.

Because strength properties depend on fabrication

history, it is important to realize that there is no unique

set of strength properties of each generic material (e.g.,

316L stainless steel, polyethylene, aluminum oxide).

Rather, there is a range of properties that depends on the

fabrication history and the microstructures produced.

Endurance limit

10

1

10

2

10

3

10

4

10

5

10

6

10

7

10

8

Cycles to failure

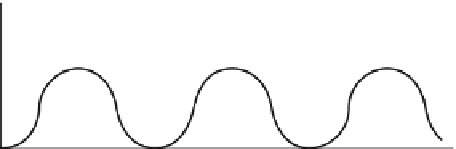

Fig. 3.1.2-11 (A) Stress versus time in a fatigue test. (B) Fatigue

curve: fatigue stress versus cycles to failure.

Conclusion

Careful attention to these details is required if laboratory

fatigue results are to be successfully transferred to bio-

medical applications.

The determination of mechanical properties is not only an

exercise in basic materials science but is indispensable to

the practical design and understanding of load-bearing

structures. Designers must determine the service stresses

in all structural members and be sure that at every point

these stresses are safely below the yield strength of the

material. If cyclic loads are involved (e.g., lower-limb

prostheses, teeth, heart valves), the service stresses must

be kept below the fatigue strength.

Subsequently where the properties and behavior of

materials are discussed in detail, it is well to keep in mind

that this information is indispensable to understanding

the mechanical performance (i.e., function) of both bi-

ological and manmade structures.

Toughness

The ability of a material to plastically deform under the

influence of the complex stress field that exists at the tip

of a crack is a measure of its toughness. If plastic de-

formation does occur, it serves to blunt the crack and

lower the locally enhanced stresses, thus hindering crack

propagation. To design ''failsafe'' structures with brittle

materials, it has become necessary to develop an entirely

new system for evaluating service worthiness. This

system is fracture toughness testing and requires the

testing of specimens with sharp notches. The resulting

Bibliography

Billmeyer, F.W. (1984).

Textbook of

Polymer Science

. John Wiley and Sons

Inc., New York.

Hummel, R.E. (1997).

Understanding

Materials Science.

Springer-Verlag,

New York.

Kingery, W.D. (1976).

Introduction to

Ceramics

. John Wiley and Sons Inc.,

New York.