Biomedical Engineering Reference

In-Depth Information

A

F

|

l

|

F

-

A

⊥

Tensile

stress

=

l

o

A

l

o

Δ

l

l

o

||

Tensile

strain

=

A

||

=

Shear stress

l

Δ

l

l

=

Shear strain

F

⊥

Fig. 3.1.2-5 Shear stress and shear strain.

Fig. 3.1.2-4 Tensile stress and tensile strain.

Elastic constants

Tension and compression

By using these definitions of stress and strain, Hooke's

law can be expressed in quantitative terms:

In tension and compression the area supporting the load

is perpendicular to the loading direction (tensile stress),

and the change in length is parallel to the original length

(tensile strain).

If weights are used to provide the applied load, the

stress is calculated by adding up the total number of

pounds-force (lb) or newtons (N) used and dividing by the

perpendicular cross-sectional area. For regular specimen

geometries such as cyclindrical rods or rectangular bars,

a measuring instrument, such as a micrometer, is used to

determine the dimensions. The units of stress are pounds

per inch squared (psi) or newtons per meter squared

(N/m

2

). The N/m

2

unit is also known as the pascal (Pa).

The measurement of strain is achieved, in the simplest

case, by applying reference marks to the specimen and

measuring the distance between with calipers. This is the

original length,

l

o

. A load is then applied, and the distance

between marks is measured again to determine the final

length,

l

f

. The strain, 3, is then calculated by:

s

¼ E

3

;

tension or compression

;

(3.1.2-2a)

s

¼ G

g

;

shear

:

(3.1.2-2b)

E

and

G

are proportionality constants that may be

likened to spring constants. The tensile constant,

E

, is the

tensile (or (Young's) modulus and

G

is the shear modu-

lus. These moduli are also the slopes of the elastic portion

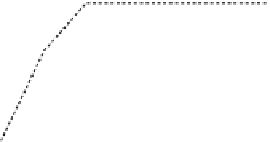

of the stress versus strain curve (

Fig. 3.1.2-6

). Since all

geometric influences have been removed,

E

and

G

rep-

resent inherent properties of the material. These two

moduli are direct macroscopic manifestations of the

strengths of the interatomic bonds. Elastic strain is

achieved by actually increasing the interatomic distances

in the crystal (i.e., stretching the bonds). For materials

with strong bonds (e.g., diamond, Al

2

O

3

, tungsten), the

moduli are high and a given stress produces only a small

strain. For materials with weaker bonds (e.g., polymers

and gold), the moduli are lower (

Hummel, 1997

). The

tensile elastic moduli for some important biomaterials

are presented in

Table 3.1.2-2

.

3

¼

l

f

l

o

l

o

¼

Dl

l

o

:

(3.1.2.1)

This is essentially the technique used for flexible

materials like rubbers, polymers, and soft tissues. For

stiff materials like metals, ceramics, and bone, the de-

flections are so small that a more sensitive measuring

method is needed (i.e., the electrical resistance strain

gage).

Isotropy

The two constants,

E

and G, are all that are needed to

fully characterize the stiffness of an isotropic material

(i.e., a material whose properties are the same in all

directions).

Single crystals are anisotropic (not isotropic) because the

stiffness varies as the orientation of applied force changes

relative to the interatomic bond directions in the crystal. In

polycrystalline materials (e.g., most metallic and ceramic

specimens), a great multitude of grains (crystallites) are ag-

gregated with multiply distributed orientations. On the

Shear

For cases of shear, the applied load is parallel to the area

supporting it (shear stress, s), and the dimensional

change is perpendicular to the reference dimension

(shear strain, g

)

(

Fig. 3.1.2-5

).