Biomedical Engineering Reference

In-Depth Information

that are tightly packed and firmly bound together. This is

the microstructure of the material that is observed at

magnifications where the resolution is between 1-100

m

m.

In pure elemental materials, all the crystals have the

same structure and differ from each other only by virtue of

their different orientations. In general, these crystallites or

grains are too small to be seen except with a light micro-

scope. Most solids are opaque, however, so the common

transmission (biological) microscope cannot be used. In-

stead, a metallographic or ceramographic reflecting mi-

croscope is used. Incident light is reflected from the

polished metal or ceramic surface. The grain structure is

revealed by etching the surface with a mildly corrosive

medium that preferentially attacks the grain boundaries.

When this surface is viewed through the reflecting

microscope the size and shape of the grains, i.e., the mi-

crostructure, is revealed.

Grain size is one of the most important features that

can be evaluated by this technique because fine-grained

samples are generally stronger than coarse-grained speci-

mens of a given material. Another important feature that

can be identified is the coexistence of two or more phases

in some solid materials. The grains of a given phase will all

have the same chemical composition and crystal struc-

ture, but the grains of a second phase will be different in

both these respects. This never occurs in samples of pure

elements, but does occur in mixtures of different ele-

ments or compounds where the atoms ormolecules can be

dissolved in each other in the solid state just as they are in

a liquid or gas solution.

For example, some chromium atoms can substitute for

iron atoms in the FCC crystal lattice of iron to produce

stainless steel, a solid solution alloy. Like liquid solutions,

solid solutions exhibit solubility limits; when this limit is

exceeded, a second phase precipitates. For example, if

more Cr atoms are added to stainless steel than the FCC

lattice of the iron can accommodate, a second phase that is

chromium rich precipitates. Many important biological

and implant materials are multiphase (

Hummel, 1997

).

These include the cobalt-based and titanium-based or-

thopedic implant alloys and the mercury-based dental

restorative alloys, i.e., amalgams.

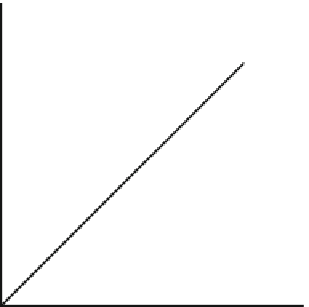

Load

(newtons)

Extension (mm)

Fig. 3.1.2-3 Initial extension is proportional to load according to

Hooke's law.

mechanical properties on microstructure is so great that

it is one of the fundamental objectives of materials sci-

ence to control mechanical properties by modifying

microstructure.

Elastic behavior

The basic experiment for determining mechanical

properties is the tensile test. In 1678, Robert Hooke

showed that a solid material subjected to a tensile (dis-

traction) force would extend in the direction of traction

by an amount that was proportional to the load

(

Fig. 3.1.2-3

). This is known as Hooke's law and simply

expresses the fact that most solids behave in an elastic

manner (like a spring) if the loads are not too great.

Stress and strain

The extension for a given load varies with the geometry

of the specimen as well as its composition. It is, there-

fore, difficult to compare the relative stiffness of differ-

ent materials or to predict the load-carrying capacity of

structures with complex shapes. To resolve this confu-

sion, the load and deformation can be normalized. To do

this, the load is divided by the cross-sectional area

available to support the load, and the extension is divided

by the original length of the specimen. The load can then

be reported as load per unit of cross-sectional area, and

the deformation can be reported as the elongation per

unit of the original length over which the elongation oc-

curred. In this way, the effects of specimen geometry can

be normalized.

The normalized load (force/area) is stress (s) and the

normalized deformation (change

Mechanical properties of materials

Solid materials possess many kinds of properties (e.g.,

mechanical, chemical, thermal, acoustical, optical, elec-

trical, magnetic). For most (but not all) biomedical ap-

plications, the two properties of greatest importance are

strength (mechanical) and reactivity (chemical). The

remainder of this section will be devoted to mechanical

properties, their measurement, and their dependence on

structure. It is significant to note that the dependence of

in length/original

length) is strain (3)(

Fig. 3.1.2-4

).