Hardware Reference

In-Depth Information

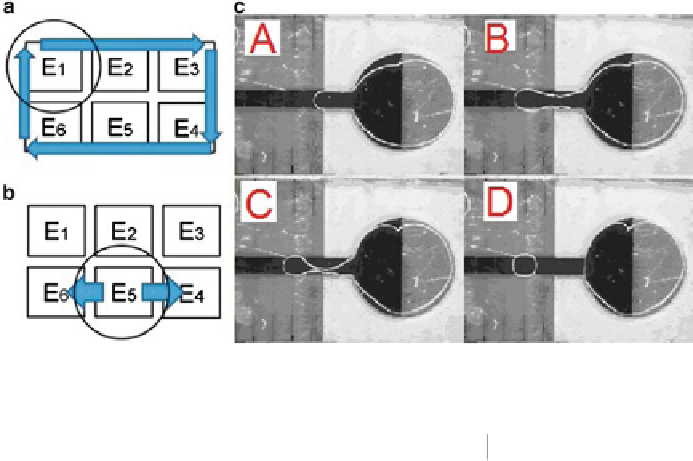

Fig. 3.3

Movement of droplets for (

a

) mixing; (

b

) splitting; (

c

) dispensing [

24

]. Steps A-D show

the procedure of pulling a droplet from the reservoir

Tabl e 3. 3

Actuation

sequences for electrodes

in the mixer

Electrodes

1

2

3

4

5

6

Actuation sequences

(ordered in time)

v

1

0

X

X

X

0

0

v

1

0

X

X

X

X

0

v

1

0

X

X

X

X

0

v

1

0

X

X

X

X

v

2

0

v

2

activation statuses are different. For example, in [

8

], the actuation voltage required

to move a droplet is 7.2 V, while the lowest voltage required to dispense a 300 pl

droplet from a reservoir is 11.4 V. Thus in the memory of the controller, these non-

zero elements of actuation matrices are recorded as the value of the corresponding

control voltages. In the following parts, we use “0” and “X” to represent deactivated

and “don't-care” status of electrodes, respectively. We also use “

v

1

”and“

v

2

”to

represent the activated status in terms of different voltages for electrodes in mixing

and splitting operations. As shown in Fig.

3.3

a, operation Mix 1 is performed on an

electrode array with two rows and three columns; at the end of mixing, the product

droplet will be split into two smaller droplets, as shown in Fig.

3.3

b. During the

mixing operation, suppose the droplet is moved counterclockwise along the loop

consisting of six electrodes. At each clock cycle, the droplet will be moved from the

current electrode to an adjacent electrode. Suppose that at time instant (clock cycle)

t

0

, the droplet rests on electrode E

1

. The actuation sequence for each electrode is

calculated and listed in Table

3.3

, and the last row in Table

3.3

corresponds to the

split operation after the completion of mixing. From Table

3.3

, we find that at each