Hardware Reference

In-Depth Information

a

b

Assay Sequencing Graph

Assay Sequencing Graph

Scheduling

Device Count Aware

Synchronous Scheduling

Device Placement

Droplet Routing

Dedicated Chip Layout

Design Gap

Electrode Classification,

Guided Pin Assignment,

and Wiring

Pin Assignment

Wiring

Chip Realization

Chip Realization

(a)

(b)

Conventional design flow

Co-design methodology

Design input

Design ouput

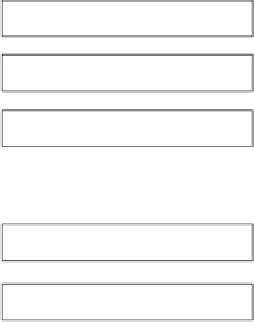

Fig. 1.17

Comparison between the conventional design flow and the chip-level biochip design

flow [

55

]

The concepts of “synchronous reaction” and “device count-aware scheduling”

are introduced in the synthesis stage. The reusability of modules can be improved,

and the number of control pins required is minimized [

55

]. Next, the modules

that correspond to these scheduled operations are placed on the biochip. Based

on the device count-aware scheduling algorithm, the number of modules and the

shapes of the modules are calculated. The placement of modules and the assignment

of resources are determined to minimize the distances that the droplets must be

transported. Electrodes are classified into three categories, i.e., bus, branch, and

device electrodes. The pin-assignment methods and wire-routing strategies for these

three categories are different. For example, the same types of devices that are used

to implement synchronous operations share the same group of control pins. In

this way, co-optimization for the synthesis result of the bioassay, pin-assignment

configuration of the biochip, and metal wire-routing solution is achieved.