Hardware Reference

In-Depth Information

Feedback from

sensors

f

T

Y

e

s

Input from the

signal generator

T phase?

Frequency divider

No

f

D

/M

f

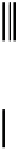

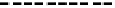

Fig. 4.2

A tunable frequency-divider controlled by the feedback from sensors

•

Method I—Software implementation:

Since the output frequency of the signal

generator can be controlled by the software, the frequency can be adjusted

dynamically during the execution of the bioassay. Recent work in a different

context, viz. to understand the reliability impact of multiple frequencies, has

demonstrated the feasibility of such a hardware setup [

16

].

•

Method II—Hardware implementation:

The tunable frequency-divider con-

trolled by the feedback from sensors can generate control signals with more than

two distinct frequencies. A tunable frequency-divider can be implemented on an

FPGA,asshowninFig.

4.2

. It will not lead to any extra cost when handling more

than two frequencies.

•

Method III—By adjusting the actuation signals for electrodes

: For an electrode

that is driven by a signal generator with a fixed pulse frequency, we can adjust

the frequency of switching on/off by changing the actuation sequences of the

electrodes. For example, we assume that the actuation signal “1” means switching

the electrode on, and signal “0” means switching the electrode off. Then, by

applying a signal sequence such as “11110000”, the frequency with which the

electrode is switched on/off will be one-fourth of the frequency associated with

the signal sequence “10101010”.

In the D/M phase, the biochip operates at a nominal frequency (for example,

f

D/M

D

8 Hz), while in the T phase, higher-frequency signals (for example, f

T

D

16 Hz) are applied to the electrodes. The time spent on dispensing and transporting

droplets can be significantly reduced with no additional degradation of electrodes or

any additional cost in hardware.

It is important to note that, the above methods can be used to generate two

or more working frequencies for biochips. For simplicity, two distinct working

frequencies are used in the simulation for D/M and T phases of the bioassay in

this paper.

Since the time spent on each dilution/mixing operation is determined by sensor

feedback rather than a pre-determined module library, we can derive a “semi-

deterministic” design for biochips when considering timing uncertainties. The

design includes the synthesis result (Sect.

4.3

), and droplet transportation paths in

each T phase (Sect.

4.4

).