Biomedical Engineering Reference

In-Depth Information

tissue

in vitro also needs a complex mechanism that can increase the

diffusion rates of oxygen and nutrients by building new bioreactor

technologies. This section introduces novel bioreactors for creating

an artificial and effective environment enhancing the diffusion of

supplements for engineered myocardial tissues.

6e.2

Bioreactors under Microgravity

Normally cultured cells can only build a two-dimensional structure

because they precipitate and adhere to the bottom of the dish by

gravity. Therefore, many attempts have been designed to prepare

engineering tissue by stirring the culture medium or employing a

three-dimensional (3D) gel culture system as artificial biomaterials

[8-10]. However, stirring the culture medium with a high shear stress

and the suppression of culture medium penetration into highly dense

cells leads to their necrosis in the tissue. To solve this problem, the

microgravity culture method is designed for fabricating 3D tissue.

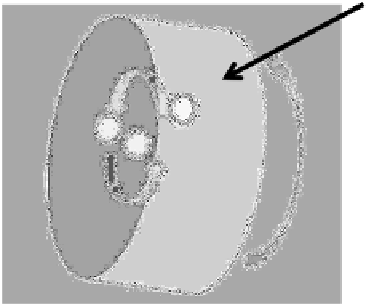

A microgravity bioreactor creates an environment providing 1/100

ground gravity by continuously varying the direction of gravity, called

rotating wall vessel (RWV) (Fig. 6e.1). The rotating vessel suspends

cells and forms 3D aggregates in the culture medium. In an RWV,

laminar flow at the surface construct is found, and the maximum

shear stress is on the order of 0.8 dynes/cm

2

, when a 120 mL RWV

contains one model construct, and the inner and outer cylinders of

Vessel

Cell

Figure 6e.1

Rotating wall vessel.