Agriculture Reference

In-Depth Information

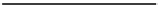

Table 5.5.

Conclusions and recommendations on the use of MA/CA for some

tropical fruit crops.

Atmosphere

Fruit

Intended use

%O

2

%CO

2

Degree of bene

fi

ts

Avocado

Transport, MAP

2-5

3-10

Good

Banana

Transport, MAP, storage

2.5

2.5

Excellent

Cherimoya

Transport, storage

2-5

3-10

Good

Durian

Transport

3-5

10-20

Fair

Lanzon

Transport

5

0

Fair

Litchi

Packaging, transport

5

20

Good

Mango

Transport

3-5

5-10

Good

Mangosteen

Transport

2

10

Fair

Papaya

Transport

2-5

5-8

Fair

Pineapple

Transport

2-5

5-10

Not determined

Sapodilla

Not determined

5

10

Fair

Sweetsop

Not determined

5

10

Fair

constraints such as chilling sensitivity, short postharvest life, and disease and

insect infestations.

It is essential to assure a sui ciently long postharvest life for tropical

fruits to be able to be distributed in distant markets. The minimum times

required for sea freight from eastern Australia to South-east Asia, Japan and

North America, and Europe are 3, 4 and 6 weeks, respectively. Minimum

shipping periods from Mexico to Europe and Japan are about 18 and 21 days,

respectively. In addition to better postharvest handling systems (i.e. optimum

harvesting time, control of insects and diseases, and the use of proper

postharvest temperature management), MA and CA can be of major benefi t to

preserve quality and to prolong postharvest life.

For example, MA has been used for more than 30 years during banana

transport from Central America to the rest of the world. Advances in MA/CA

technology during transport have been implemented, and the technology is

much more promising for tropical fruits. Atmospheres for transport have been

developed that are passive (MA), semi-active or active (CA). The semi-active

systems are those in which a selected atmosphere is created in the container

immediately after loading, after which the container is closed and no further

control of oxygen and carbon dioxide levels is carried out. Atmospheres are

created by an oxygen sensor telling a valve to open or close to allow more air to

enter the container to increase the oxygen level, or nitrogen to reduce oxygen

levels. Carbon dioxide can also be monitored and a valve controls the amount

of air entering to prevent the carbon dioxide from getting higher than the

desired level.

The major question is whether the additional costs of applying the

MA or CA treatments are recovered in the increased storage life and quality