Environmental Engineering Reference

In-Depth Information

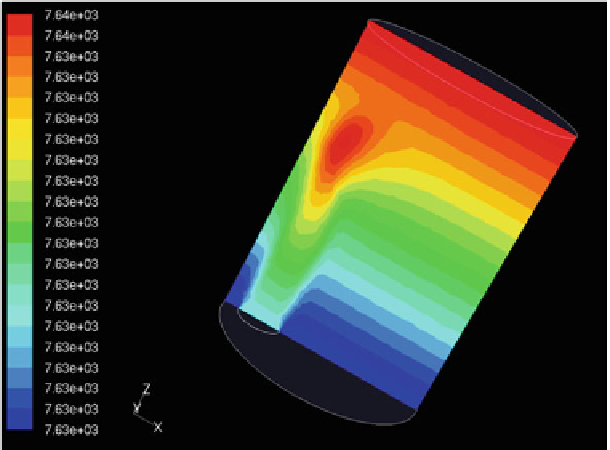

Fig. 5

Distribution of the kinetic energy in the entire ladle system for the same model of previous

figures. The

colour-scale bar

and numbers on the left border indicate the values of the kinetic energy

in units of g m

2

s

−

2

4 Conclusions

In this paper, we have presented numerical simulations of two-phase flows in a scaled

air-water model of an industrial gas-stirred ladle using the

FLUENT 6.3

code. We

find that the intensity of agitation and turbulence in the ladle increases by increasing

the gas flow rate at the nozzle exit. As expected, an eccentric gas blowing improves

the mixing as it enforces the reduction of inactive flow regions, or dead zones, just

below the recirculating liquid flow at the bottom of the ladle. In addition, changing

the diameter of the porous plug hardly affects the flow pattern as the rising of the

gas bubbles is dominated by inertial forces near the nozzle exit and by gravitational

forces at higher heights. The results are in excellent agreement with experimental

observations of eccentric gas injection models as well as observations and numerical

calculations of plume development and behaviour.

References

Aoki J, Thomas BG, Peter J, PeasleeKD (2004) Experimental and theoretical investigation ofmixing

in a bottom gas-stirred ladle. In: Proceedings of the association for iron and steel technology

(AISTech 2004), vol I, pp 1045-1056

Balaji D, Mazumdar D (1991) Numerical computation of flow phenomena in gas-stirred ladle

systems. Steel Res 62(1):16-23

Search WWH ::

Custom Search