Environmental Engineering Reference

In-Depth Information

better resolution was needed. Also, because the motion of the bubbles is not strictly

vertical, a more detailed characterization of the curtain was required.

3 Methodology

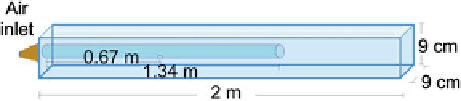

A new device that allowed control of the size and number of the generated bubbles

was developed. Very small, equally sized holes were made on a tube using a laser

cutting machine. One end of the tube was sealed, and the other was connected to a

continuous supply of air. To create an almost uniformflow inside the bubble generator,

an inner tube was introduced as shown in Fig.

4

.

The characterization of the bubble curtain was conducted in the wave flume at the

“Coast and Ports Laboratory” at the Engineering Institute of the UNAM, where the

environment is controlled. A video camera with a speed of 120 frames per second

was used. To ensure a constant flow of air, the pressure is monitored with a mercury

manometer connected between the air pump and the bubble generator as shown in

Fig.

5

.

The study was divided into three stages. First, the behavior of bubbles generated

by one hole was analyzed. Bubbles have a spiral trajectory as they travel upwards.

Fig. 4

Diagram of the bubble generator

Fig. 5

Experimental setup to characterize the behavior of the bubbles

Search WWH ::

Custom Search