Biomedical Engineering Reference

In-Depth Information

traditional metal testing, where there can be large hardness variations at

constant elastic modulus due to local microstructural effects associated

with dislocation motion. Hardening mechanisms such as grain size

refinement due to mechanical work are simply unavailable in the non-

metal materials found in the natural world. In the context of instrumented

indentation testing, the hardness is the mean supported contact stress,

17

a

measure of the total resistance to deformation, regardless whether the

deformation is elastic, plastic,

18

viscous,

19

or due to crushing fracture.

20

As such, on average, over a wide range of biological materials, the

hardness is not an independent material property but depends directly on

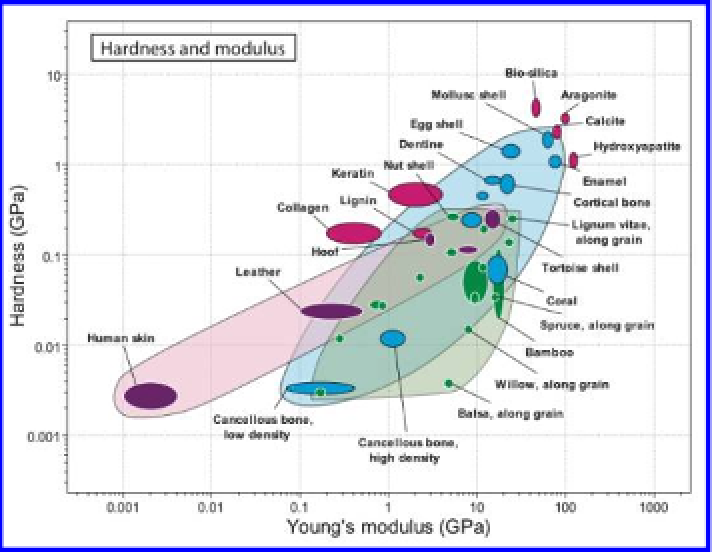

Figure 1-10. The relationship between elastic modulus and “hardness” in biological

materials.

Although biological materials often do not exhibit elastic-plastic

responses, there are reasons to consider nanoindentation testing as

particularly useful for their mechanical characterization. Nanoindentation

testing is well-suited to study the composite nature of biological

Search WWH ::

Custom Search