Biomedical Engineering Reference

In-Depth Information

material parameters are with respect to common error sources

encountered in nanoindentation experiments, as well as to establish

appropriate algorithms to alleviate and smooth data fluctuations.

Different indenters (

e.g.

pyramidal, conical, spherical) can be used for

different systems, and the careful use of plural indenters may help to

deduce more material parameters.

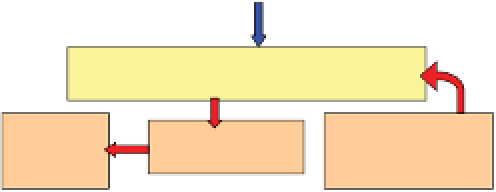

Film and substrate

elastoplastic properties,

multilayer and material

microstructure, interface

toughness, etc.

Shape factors of

P-

h

curve, hardness,

stiffness, indent

profile, crack

geometry, etc.

Forward

analysis

Established dimensionless relationships

among multiple most important variables

Determined

material

properties

Data measured from

nanoindentation

experiment

Iteration and error

minimization

Reverse analysis

Figure 6-10. Computational modeling of indentation: The general forward (blue) and

reverse (red) analysis algorithms, which allow the determination of the mechanical

properties of various material structures using instrumented indentation.

The theory established from computational modeling of indentation

must be closely tied with experiment, with theory both explaining

experimental findings and predicting phenomena for experiments to

explore; in turn, the experiment could validate and improve the theory.

In use, several issues need to be paid special attention between

experimental data and theory, otherwise significant error may emerge.

91

Most indentation techniques proposed in literature are based on

homogeneous, isotropic (and identical tensile and compressive

behaviors), stress-free, power-law material, and assuming ideal indenter

geometry (and also the specimen surface must be sufficiently flat), which

may be referred to as the ideal model. An ideal model is also required for

the analysis of experimental indentation data, where phenomenological

material parameters may be extracted. If the real specimen does not

conform to the five basic assumptions of the ideal model, errors may

occur when one tries to use the indentation technique to extract

elastoplastic properties from the indentation test. Nevertheless, as shown

Search WWH ::

Custom Search