Biomedical Engineering Reference

In-Depth Information

approach involves the sampling of a large number of individual

indentation responses across the material surface and using the obtained

range of responses to bound the inferred microstructure in terms of phase

length-scale

18

and mechanical properties.

19

Substantially more effort is

required to develop a robust method for the mechanical characterization

of composite materials by indentation without the need for finite element

analysis.

20

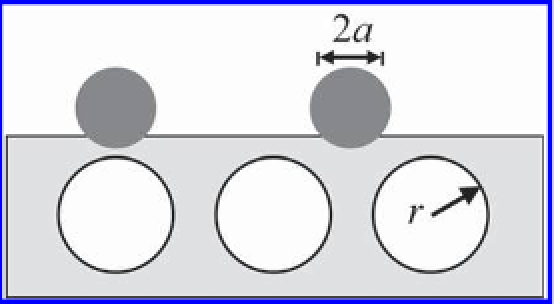

Figure 5-8. Schematic illustration of indentation of a composite material, in which the

observed response depends on the placement of the indenter relative to microstructural

features and the relative indentation and microstructural length-scales (

a

vs

r

).

5.3.

Layered systems

The analyses presented thus far have been oriented towards bulk

materials. However, in the majority of soft tissue indentation tests, the

soft tissue layer of interest (

e.g

. cartilage) is supported by a much stiffer

substrate (frequently bone). Just as in the case of composite materials,

the indentation of a layered structure introduces a length-scale into the

indentation problem, where the indentation contact depth or contact

radius (

h

c

or

a

, respectively) are considered relative to the layer thickness

tissue indentation testing relies on the finite thickness of the tissue layer,

considering the underlying bone as a rigid substrate.

21

The elastic

expression employed for analysis is thus a modification of the bulk flat-

Search WWH ::

Custom Search