Biomedical Engineering Reference

In-Depth Information

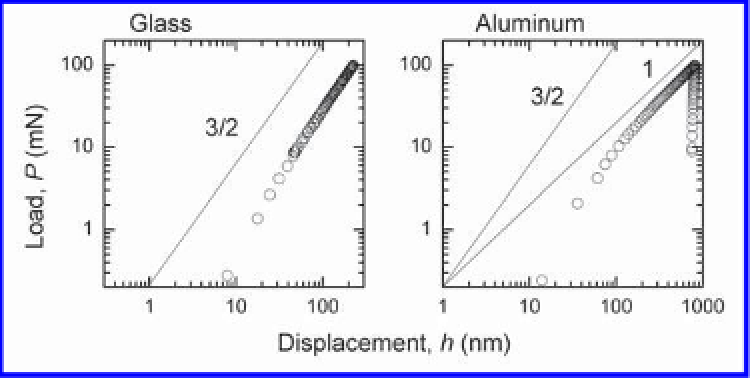

Figure 5-4. Elastic-plastic indentation responses for a sphere on fused silica glass and

aluminum. The fused silica remains remains elastic while the aluminum demonstrates the

onset of plastic deformation and a transition from

P

~

h

3/2

to

P

~

h

behavior at

displacements larger than 100 nm.

is the relative curvature between the indenter and the residual impression

on the sample surface. The challenge lies in identifying the elastic depth

h

e

as a function of the total depth, and separating out this relative

curvature term. In this regard a “partial unloading” protocol has been

developed for using multiple loading and (partial) unloading cycles—

a stepwise indentation protocol—to assist with identification of the

plastic depth and allow for elastic modulus measurements. The interested

reader is referred to Ref. 13 for further details; in many cases the

advantage of using a spherical indentation probe is the avoidance of the

onset of plastic deformation. For this reason spherical probes are often

used for elastic, viscoelastic and poroelastic analysis and less commonly

for elastic-plastic problems.

4.2.

E and H deconvolution for sharp indentation

Elastic-plastic indentation testing typically uses a sharp “geometrically

similar” pyramidal (or, less commonly, conical) probe with a fixed

probe tips (indenter radius

R

i

= 50-100 nm), the large strains in the

Search WWH ::

Custom Search