Geology Reference

In-Depth Information

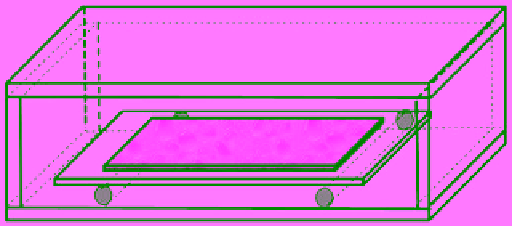

Figure 6.26

Thermal etching box with transparent glass bot-

tom and top covers, two stainless steel rollers to support the

glass plate and DMT thin section of ice; crushed ice (not

shown) inside the box on two sides maintain high humidity.

0.5 mm

controlled further by keeping the glass plates containing ice

thin sections inside a closed chamber with near saturated

environment, as shown in Figure 6.26 containing a little

crushed ice or snow around the corners at the bottom.

If the top and the bottom covers of the thermal etching

box are transparent, as shown in Figure 6.26, thin sec-

tions can be examined with an optical microscope

through transmitted light without disturbing the environ-

ment of the sections. Polarized light can also be used to

delineate different grains and thereby bring out grain

structures. The author (N. K. Sinha) has found that sur-

face imperfections of ice thin sections can be revealed

very prominently under transmitted light, but propagat-

ing at oblique angles, rather than light traveling at right

angles to the surfaces of thin sections. This is actually

very important to remember while photographing sur-

face characteristics of thin sections of any transparent

materials, like ceramics and rocks. For ice, in particular,

the use of obliquely transmitted light has been found to

be extremely useful for micrographing sublimation pits

(Higuchi etch pits) as well as thermally or chemically

etched grain or subgrain boundaries in ice. Oblique light-

ing brings out perceptions of depth in a clear manner and

provides a pseudo‐three‐dimensional effect. Example of

the quasi‐3D effect of oblique transmitted lighting can be

seen in Figure 6.22 for sublimation pits and in Figure 6.27

for thermally etched grain boundaries in pure ice.

The conventional technique of making thin sections

and observations under polarized light has been proven

to be inadequate for fine‐grained ice but of high density,

such as common granular ice. It has been proved to be

useless if the average grain diameters are small, for exam-

ple, less than 0.3 mm. This type of hopeless situation can

be avoided in a very simple way by making use of thermal

etching. An example is shown in Figure 6.27. In this case

a drop of water at a freezing temperature was spat cooled

to simulate in‐flight icing due to the impact of super-

cooled water droplets on aircraft structures at subzero

temperatures. Following solidification on the surface of

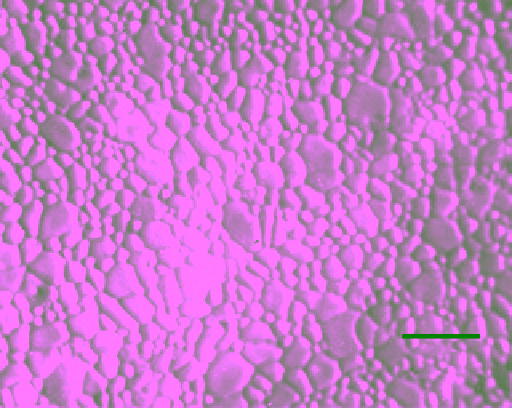

Figure 6.27

Grain size distribution in spat‐cooled (a condition

similar to in‐flight icing) and almost instantly frozen drops of

distilled water, revealed by sublimation under controlled con-

ditions; note that extremely small grains with diameters of

about 50 nm can also be revealed by this method (micrograph

by N. K. Sinha, unpublished).

an aluminum (of the type used in aircrafts) plate, the

specimen was simply placed inside a thermal etching box,

as shown in Figure 6.26, at −10 °C and let the sublimation

do the work. In this case, the micrograph was taken by

using oblique, but reflected light under a microscope.

The substructures of sea ice can be examined by ther-

mal etching in a very simple and direct manner, provided

the surfaces and thin sections are prepared by the DMT

technique. To illustrate this, a 0.33 m long full‐depth core

of FY S3‐type sea ice was sampled from the middle of

Strathcona Sound in Baffin Island, away from the shore

line, on 26 November, 1975 during a polar night. The

entire 30 km long sound was full with a uniform cover of

land‐fast sea ice. The air temperature was −32 °C and the

air was calm. Due to the presence of the snow cover, the

ice was relatively warm. Immediately after extraction, the

core was stored in a clear core bag under ambient condi-

tions until processed. The ice was columnar grained with

the

c

axis of the grains in the horizontal plane and ori-

ented preferably along the length of the sound and, there-

fore, parallel to the tidal current. Figure 6.28 shows an

optical micrograph of a horizontal thin section (prepared

using the DMT technique) at a depth of 0.3 m. The salin-

ity of this section, measured from the microtome‐shaved

ice, was found to be 12

‰

. The thin section was prepared,

using a freshly sharpened microtome blade, at −10 °C

purposely for the examinations of entrapments as liquid

in brine pockets because that was close to the in situ tem-

perature of the ice in the ice sheet under a blanket of

snow. The micrograph in the top image of Figure 6.28