Geology Reference

In-Depth Information

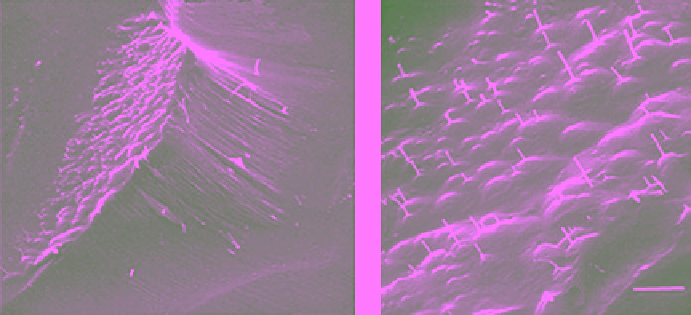

(a)

(b)

10

μ

m

Figure 6.24

Scanning electron micrographs of a replica showing (a) a sublimation pit for ice surface with

c

axis

inclined, but

a

axis parallel to the surface; and (b) details of numerous pyramidal dislocation etch pits with dislo-

cation cores (looks like whiskers) on the inclined basal face (SEM by N. K. Sinha, unpublished).

in optical microscopes or even SEM. The specimen sur-

faces have to be chemically etched to bring out the details

of the surface structures.

Etching evokes a notion of either applying a chemical

agent on the surfaces of metallographic specimens or

immersing them in the etching solution. The objectives

are to dissolve metals away from the specimen surface

defects in a selected manner. Usually, the grain bounda-

ries are etched more rapidly than the surface of the

grains because the grain boundaries are relatively at

higher energy levels. The etching solution may also dis-

solve the various grains differentially according to the

crystallographic orientation of the surfaces exposed to

the chemicals. The etched boundaries affect the reflectiv-

ity of the light and reveal their presence when viewed

through microscopes in reflected lights. The etched sur-

face features can also be examined by the SEM for higher

magnifications and greater depth of field.

The etching of crystal surfaces and producing etch

pits is widely accepted as a powerful tool for observa-

tions of structural aspects of materials including lattice

defects and their behavior [

Gilman and Johnston

, 1956].

The problems and complexities encountered in ice, how-

ever, are significantly different from those faced in other

materials mainly because the working temperatures with

ice are so close to its melting point. Removal of the sur-

face atoms by chemical actions in addition to the simul-

taneous processes of sublimation complicates the matter

enormously for ice. However, the fact that ice is always

extremely hot also provides significant advantages over

other materials, and this has been demonstrated earlier

and more will be covered below.

Toward the end of 1940, methods for determining the

orientation of

c

axis and the size distribution of grains in

polycrystalline ice were developed by

Seligman

[1949] and

Schaefer

[1950], but not the

a

axis. In fact, attempts to

etch and replicate ice surfaces used by

Schaefer

[1950],

inadvertently led to the development of the Higuchi

method and has been presented earlier. Another high‐

temperature aspect of ice is the internal melting.

Nakaya

[1956] showed that the orientation of

a

axis can be deter-

mined, at least for single crystals, by generating Tyndall

figures inside the crystal. These figures develop due to

internal melting. The absorption of infrared radiation

from light beams is sufficient to melt the ice internally.

Kuroiwa and Hamilton

[1963] showed that a 5% or 6%

solution of Formvar in ethylene dichloride was a suita-

ble etchant for developing dislocation etch pits on the

basal plane corresponding to the emergence of nonbasal

dislocations on this surface. Dislocation etch pits on the

(0001) plane were found to be hexagonal pyramidal, in

agreement with the earlier observations of

Muguruma

[1961].The earlier investigator's conclusions on the asso-

ciation of etch pits with dislocations were based on indi-

rect, though convincing, evidence, whereas the latter

workers provided direct evidence by showing etch tracks

as evidence of the movement of dislocations under

stress. Some of these observations were later confirmed

by

Levi et al.

[1965]. A significant progress was then

made by

Kuroiwa

[1969], who looked at Formvar replicas

using a scanning electron microscope with the resolution

and depth of field required for investigating the three‐

dimensional topography of etched surfaces of ice.

However, dislocations are line defects [

Weertman and

Weertman,

1964], and the correspondence between non-

basal dislocations and pyramidal etch pits on basal plane

was established not directly but by inferences. Indirect

methods, similar to the classic examples set by

Gilman

and Johnston

[1956] for lithium fluoride, were used.

Gilman and Johnston related point‐bottomed etch pits