Geology Reference

In-Depth Information

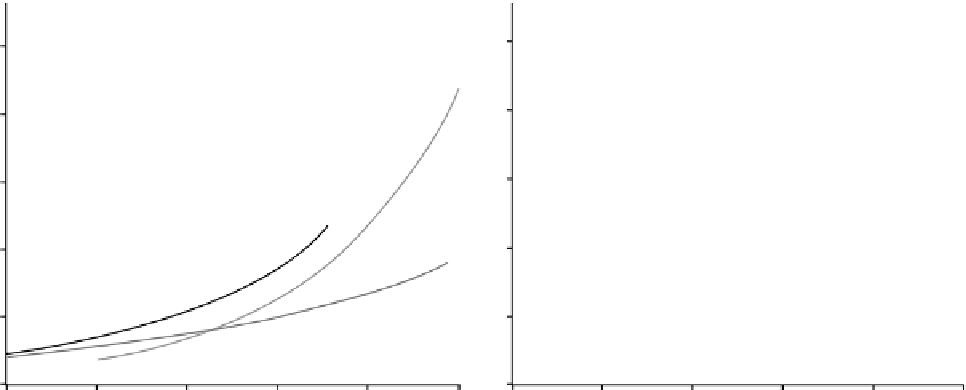

Particle contact ratio = 0.1

Particle contact ratio = 0.2

1. 0

1. 0

0.8

0.8

0.6

0.6

0.4

0.4

0.2

0.2

0

0

100

200

300

Density (kg/m

3

)

400

500

600

100

200

300

400

500

600

Density (kg/m

3

)

Figure 3.23

Variation of effective thermal conductivity of snow with snow density computed from a one‐

dimensional heat transfer model suggested by

Satyawali and Singh

[2008] for three shapes of ice grain inclusions

in the snow (spherical, cylindrical, and cubical) and two characteristic ratios of grain size to grain spacing. Snow

temperature of −5 °C was used in the calculations. Empirical results from the model by

Strum et al.

[1997] are

also included [

Satyawali and Singh,

2008].

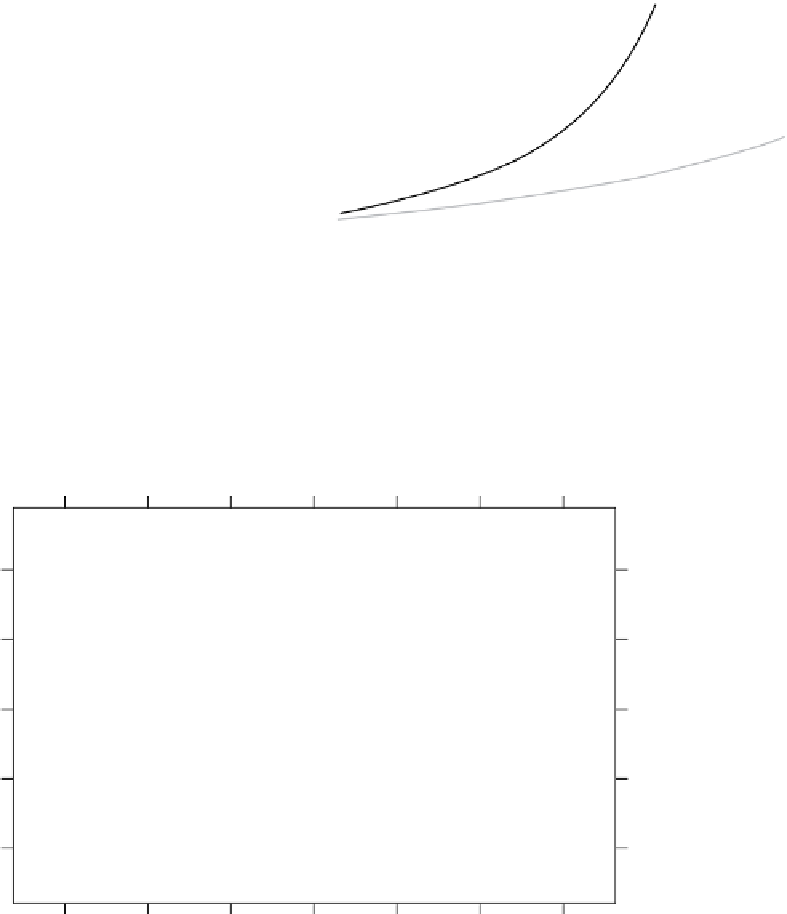

0.5

Wetted and refrozen

Slabs of increasing hardness

Slabs going to depth hoar

0.4

New to fine grained

0.3

Increasing hoar metamorphism

0.2

0.1

2

4

6 8 10

Snow code (Table 3.6)

12

14

Figure 3.24

Trajectory of thermal conductivity of snow over sea ice, measured during SHEBA program in the

Beaufort Sea, winter of 1997. Snow code at the horizontal axis is presented in Table 3.6. Symbols are explained

in Figure 3.21 (adapted from

Sturm et al.

[2002], Figure 5, with permission from AGU).

0.29 W/m · K for ubiquitous wind slab. The study presented

a trajectory of thermal conductivity of the snow as it

evolves through different phases in winter (Figure 3.24).

The code for snow types is given in Table 3.6. New snow

has low density and therefore low thermal conductivity. As

snow settles and becomes more compacted,

K

s

increases.

If the fine‐grained snow is transported by the wind,

grains will be broken and their size is further reduced.

Consequently, when drifting snow settles, a wind slab will

form through sintering, producing more compacted snow

with higher

K

s

values. Following that, a steep temperature

gradient within the snow depth will cause the slab to