Biomedical Engineering Reference

In-Depth Information

450

Routing-oblivious synthesis

Routing-aware synthesis

400

350

300

250

200

150

100

110

120

130

140

Array Size (number of electrodes)

Figure 2.9

Assay completion times (with droplet transportation time included) for [15] and for the pro-

posed routing-aware synthesis method.

Defective cells

To p glass plate

400

T

300

200

100

0

Bottom

10

10

X

5

Y

5

0

0

(a)

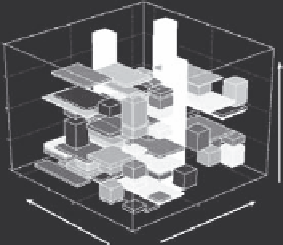

(b)

Figure 2.10

(a) A defective 10 × 10 microfluidic array; (b) reconfiguration results for postsynthesis defect

tolerance.

that one optical detector is rendered defective after manufacturing. Thus, the

operations assigned to this detector have to be remapped to other detectors.

The modified synthesis method proposed in Section 2.3.1 is used here to carry

out the reconfiguration so that these manufacturing defects are tolerated. The

reconfiguration results are shown in Figure 2.10b. This new design allows the

protein assay to operate on this defective biochip with an increase of only 7%

in the completion time; that is, the completion time is now 387 s.

2.4.3 results for Presynthesis Defect Tolerance

We next evaluate the presynthesis defect tolerance that is achieved for

the protein assay using the enhanced routing-aware method described

in Section 2.3.2. We first use this method to find a desirable solution that