Biomedical Engineering Reference

In-Depth Information

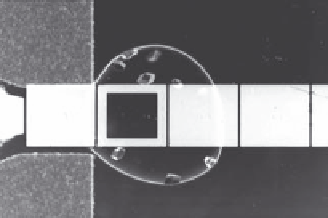

Figure 1.5

Lysozyme crystals obtained on-chip at 5× and 20× magnifications.

1 µL of protein and 1 µL of precipitants were dispensed by programmed

Hamilton syringes [42] in each well of a 96-well plate containing paraffin oil.

Microbatch crystallization has been recently demonstrated in micropipettes

in 1 µL droplets by DeTitta's group at Hauptman Woodward Institute (HWI),

where the precipitant and the protein solutions are loaded manually into

a microcentrifuge tube, centrifuged, collected in a micropipette, and then

sealed [43]. Despite efforts to reduce the protein volumes, these processes

still consume a significant amount of protein and are labor-intensive.

Robotic automation has emerged as the dominant paradigm in state-of-the-

art high-throughput protein crystallization. However, robots are slow, very

expensive, and require high maintenance. Currently, there are only a few

automatic crystallization systems that are commercially available. Douglas

Instruments' Oryx 8 [44] can perform both microbatch and vapor diffusion

methods on protein samples in the range of 0.1-2 µL. Gilson's robotic work-

stations [45] can also perform both microbatch and vapor diffusion on protein

samples of about 1 µL. Syrrx, a rational drug design company, manufactures

a robotic system [46] for protein crystallization utilizing 20 nL to 1 µL protein

samples. State-of-the-art robotic systems at HWI's NIH-funded Center for

High-Throughput Crystallization have a throughput of 69,000 experiments

per day for setting up microbatch crystallization conditions, that is, a 96-well

plate could be setup every 2 min. Each screening condition still requires

0.4 µL of protein. These semiautomatic systems do not encompass ideal

high-throughput configurations, requiring user intervention for multiple

tray processing as well as suffering from other material-processing issues.

As most of the work performed with these systems is not on a large scale,

the automation of storage and handling of plates was not addressed in these

systems [47]. Such industrial systems, even though they are capable of setting

up thousands of crystallization screens a day, are prohibitively expensive for

academic research laboratories [48]. Therefore, affordable high-throughput

automation functionality of an industrial system is still needed.

Recent work has shown the feasibility of carrying out protein crystalli-

zation on digital microfluidic biochips. In [38], Srinivasan et al. presented