Biomedical Engineering Reference

In-Depth Information

Next, a second pin-actuation sequence is applied to route droplets to their

target wells. The overall routing steps takes little time because all the wells

can be filled using only two pin-actuation sequences.

6.1.3 Chip Testing

To ensure reliability, the proposed chip design needs to be tested thoroughly.

We only focus here on a structural test where the goal is to route the test

droplet to traverse the target array for defect detection. In this section, we

discuss the adaptation of the parallel scan-like test presented in Chapter 4

(Subsection 4.1.1) to our chip design.

As presented in Chapter 4, the parallel scan-like test includes a cost-effec-

tive fault detection and a rapid diagnosis method based on test outcomes.

Given a microfluidic array, the scan-like test is carried out in parallel using

multiple droplets. Each column/row in the array is associated with a test

droplet and its “target region.” A target region for a droplet includes the cells

that are traversed by this droplet.

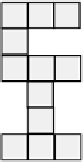

Here we adapt the parallel scan-like method to a well-plate design. As men-

tioned in Subsection 6.1.1, our well-plate design can be viewed as a special

case of a two-dimensional array where parts of the array are occupied by

wells and segregation walls. Unoccupied electrodes between wells are used

as transportation pathways.

We focus on the testing of the transportation pathway since defects in the

transportation pathway will not only block well loading but also affect drop-

let routing among different well units. Note that the transportation pathways

are in fact composed of columns/rows of electrodes. Therefore, we should be

able to test these transportation pathways in parallel in the same way as the

columns and row test in the proposed parallel scan-like test procedure, as

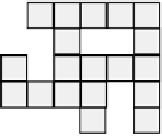

shown in Figure 6.11.

Source

Capacitive sensing

circuit

Sink

Figure 6.11

Parallel scan-like test on multiwell chip.