Biomedical Engineering Reference

In-Depth Information

Source

Source

Sink

Sink

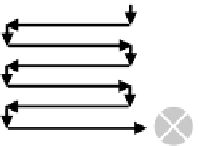

Figure 4.1

Illustration of a single-droplet scan-like test using a single droplet.

detect an electrode-short defect, a test droplet needs to traverse the two adja-

cent electrodes that are involved in the short. The test droplet will reside

in the middle of the two shorted electrodes, which are activated simultane-

ously; there will not be sufficient overlap area with the next electrode for

further transportation.

Most prototype digital microfluidic devices consist of a two-dimensional

(2-D) a r ray of elect rodes w it h one or more sou rces a nd si n k is, t hat i is, reser voi rs,

on the boundary, as shown in Figure 4.1 [25]. In this regular structure, elec-

trodes are carefully aligned in columns and rows. We next describe the par-

allel scan-like test method, named thus because it manipulates multiple test

droplets in parallel to traverse the target microfluidic array, just as test stimuli

can be loaded in parallel to multiple scan chains in integrated circuits.

We first describe the special case of a single test droplet. We determine the

pathway for the test droplet, irrespective of the bioassay operation, as shown

in Figure 4.1. Starting from the droplet source, the test droplet follows the

pathway to traverse every cell in the array, and it finally reaches the sink.

During concurrent testing, a test droplet is guided to visit the available cells

in accordance with a predetermined path. If the target cell is temporarily

unavailable for testing, that is, it is occupied by a droplet or it is adjacent to

active microfluidic modules, the test droplet waits in the current position

until the target cell becomes available. The test outcome is read out using a

capacitive sensing circuit connected to the electrode for the sink reservoir,

as shown in Figure 4.2. The figure shows details about the setup and how it

was validated. This single-droplet scan-like algorithm is easy to implement.

Moreover, the test plan is general, in the sense that it can be applied to any

microfluidic array and for various bioassay operations.

However, in this simple test procedure method,

N

×

M

steps (clock cycles for

droplet actuation) are needed for the test droplet to traverse an

N

×

M

micro-

fluidic array. As a result, the test time may be excessive for large arrays. For

example, a 600,000-electrode array manufactured by Silicon Biosystems (based

on dielectrophoresis) will require 600,000 clock cycles [68]. At a typical actua-

tion clock frequency of 1 Hz, this amounts to 7 days of test application time!

Moreover, in online testing, the test droplet may have to be stalled several

times, and each time a long waiting period may be necessary. Finally, the test