Chemistry Reference

In-Depth Information

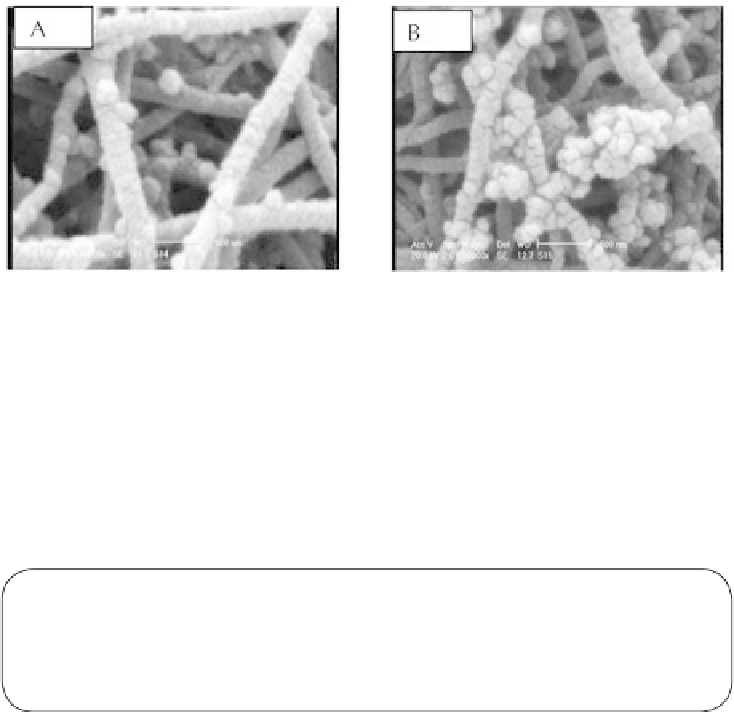

Figure 8.2 shows SEM photomicrograph of PPy coated electrospun nanofi ber. A

uniform layer of PPy is deposited on the nanofi bers surfaces. Average fi ber diameter

for uncoated nanofi bers, electrospun from 10 and 15% concentration, was 230 nm

and 390 nm, respectively. After coating process average fi ber diameter increases to

350 and 500 nm. It means that a layer of PPy with the thickness of approximately 120

nm was coated onto the nanofi bers. Measurement of the electrical conductivity of the

coated mats shows electrical conductivity in the range of 10

-3

to 1 S/cm depending on

the chemical coating conditions such as amount of the pyrrole in the coating process

and the mole ratio of the FeCl3 to the used pyrrole.

Figure 8.2.

SEM photomicrograph of PPy coated electrospun PAN nanofiber at 15% (A) and 10%

(B) concentration.

CONCLUSION

Possibility of the chemical deposition of PPy on the surface of the electrospun PAN

nanofibers is shown. Diameter of the nanofibers is governed by the concentration of

the electrospun PAN solution. A thin layer with the thickness of 120 nm is formed

onto the nanofibers surface. The electrical conductivity of the coated nanofiber mats

depends on the coating conditions and reaches to 1 S/cm.

KEYWORDS

•

Coating

•

Electrospinning

•

Nanofiber

•

Polypyrrole

Search WWH ::

Custom Search