Chemistry Reference

In-Depth Information

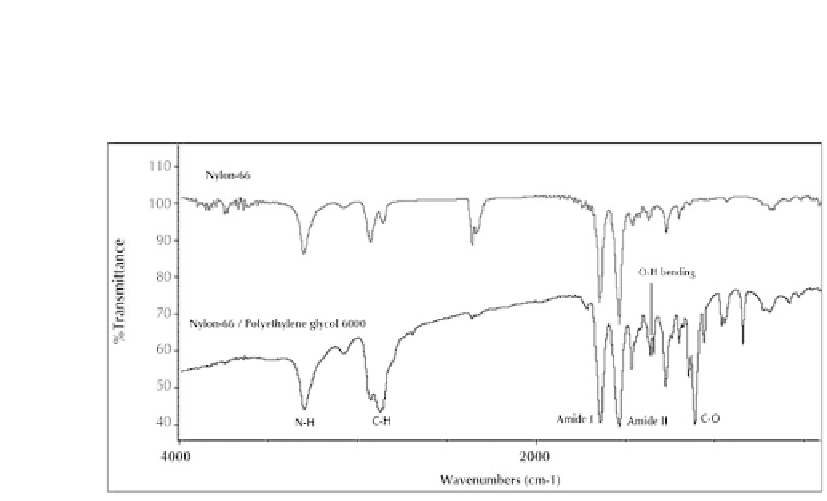

to C-O-C stretching. These two last peaks indicate the existence of PEG between the

polymer chains of nylon 6,6 and prove that the composite sample in fact is a PCM/

polymer nanofibrous structure.

Figure 6.4.

FTIR spectra of Nylon 6,6 and Nylon 6,6/PEG nanofibers.

Thermal Properties of Electrospun Nanofibers

In order to analyze the thermal properties of nylon 6,6/PEG nanofiber, pure nylon 6,6

nanofiber mat, and nylon 6,6/PEG nanofiber mats at the blend ratio of 100/50 and

100/130 were chosen. Their DSC thermograms are shown in Fig. 6.5. It is clear that

the pure nylon 6,6 nanofiber mat has no phase change peak, no heat capacity, and

therefore no ability to heat storage. However, nylon 6,6/PEG samples have melting

and crystallization peak. Phase change points and latent heat of phase changes are

shown in Table 6.2. It is clear that increasing PEG content in the blend nanofibers has

a little effect on the phase change temperatures, but strongly affects the latent heat of

phase changes. Figure 6.6 summarizes the theoretical and the experimental values of

the latent heat for the blend nanofibers. From the theoretical point of view, the en-

thalpy values of nylon 6,6/PEG composite nanofibers calculated by multiplying the

latent heats of pure PEG and its mass percentage in the composite structure. Figure 6.6

shows that all the experimental values were lower than their corresponding theoreti-

cal values. It can be explained by retardation of crystallization process of PEG in the

composite structure during electrospinning; because firstly, the cooling of nanofiber

and evaporating of solvent during the moving of jet through the air gap did not let the

molecular chains of PEG to form a fine crystalline structure in the nanofiber due to

being taken place in a little fraction of a second; and secondly, the hydrogen bonding

between the hydroxyl group of PEG and carbonyl group of nylon 6,6 also hindered

the crystallization process. So, it is concluded that the crystalline areas of PEG in the

composite nanofibrous structure are very tiny and encircled by hydrogen bondings.

These led to lower crystalline areas of PEG and higher deviation of enthalpies from

theoretical values. It is worthy to state that the diluents effect of nylon 6,6 in the com-

posite structure also affects the variation of enthalpy values.

Search WWH ::

Custom Search